Work Order Management for Manufacturing

Transform your production process with our Work Order Management software. Plan, execute, and monitor tasks to maximize efficiency, accountability, and cost control in your job shop or manufacturing facility.

Key Benefits

- Boost efficiency by tracking and scheduling tasks, reducing downtime, and increasing productivity.

- Optimize resource usage by managing materials, equipment, and personnel effectively.

- Maintain cost control with progress monitoring and resource consumption tracking.

- Ensure high-quality output through detailed tracking and quality checkpoints.

- Achieve regulatory compliance with accurate documentation and audit trails.

- Improve customer satisfaction through timely and efficient work order execution.

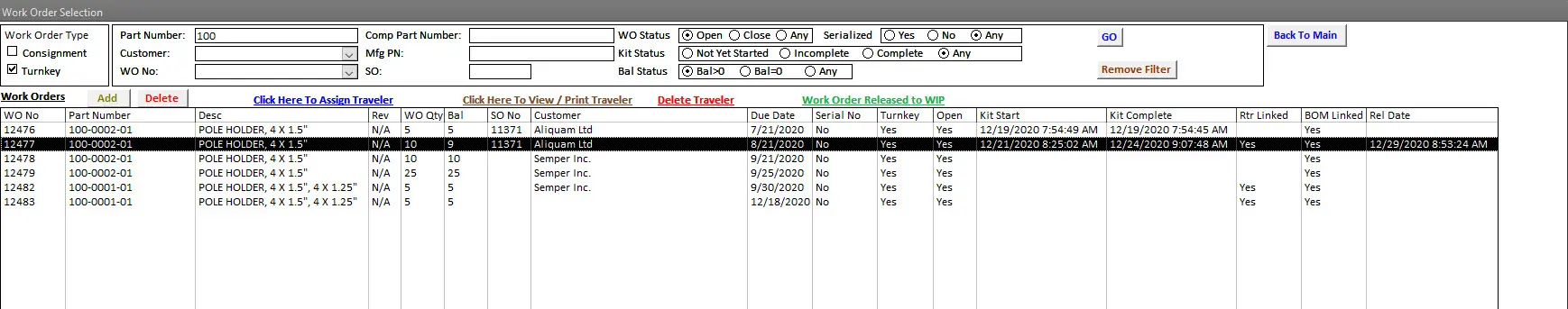

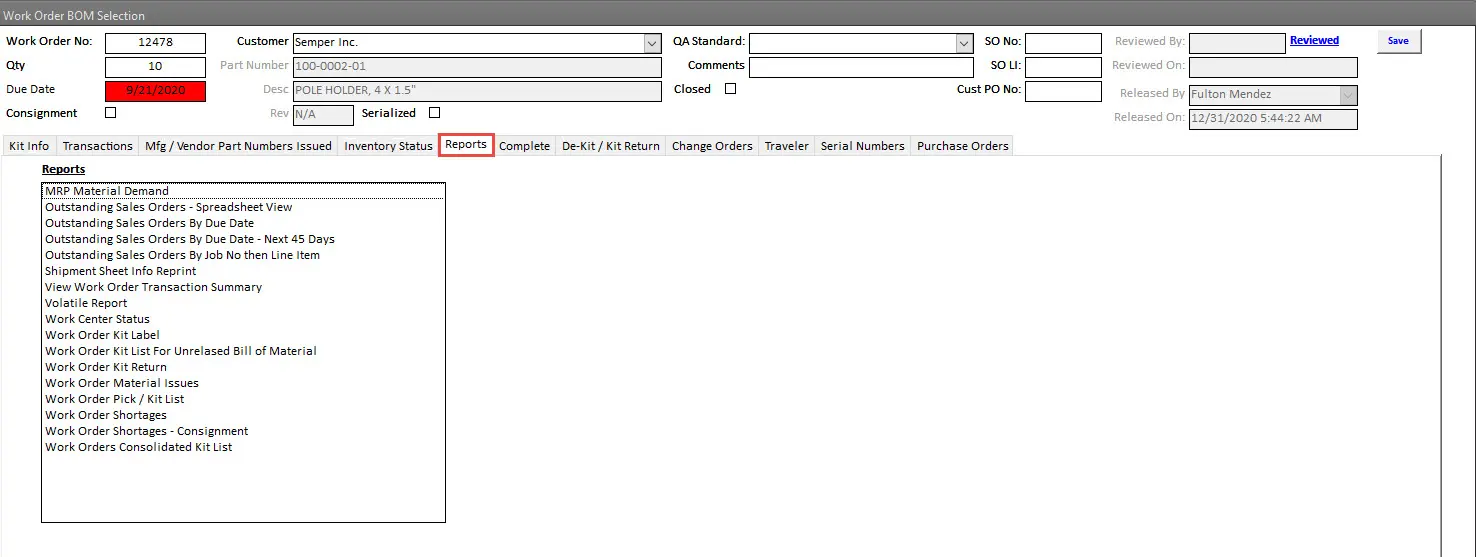

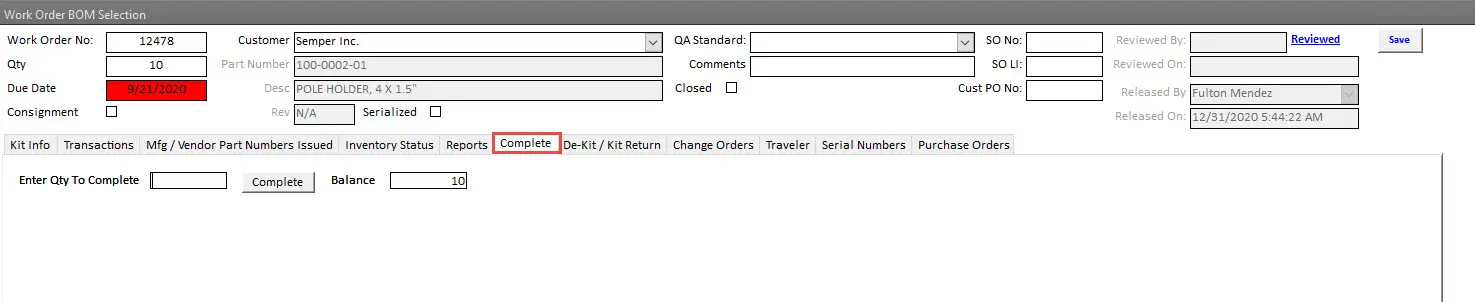

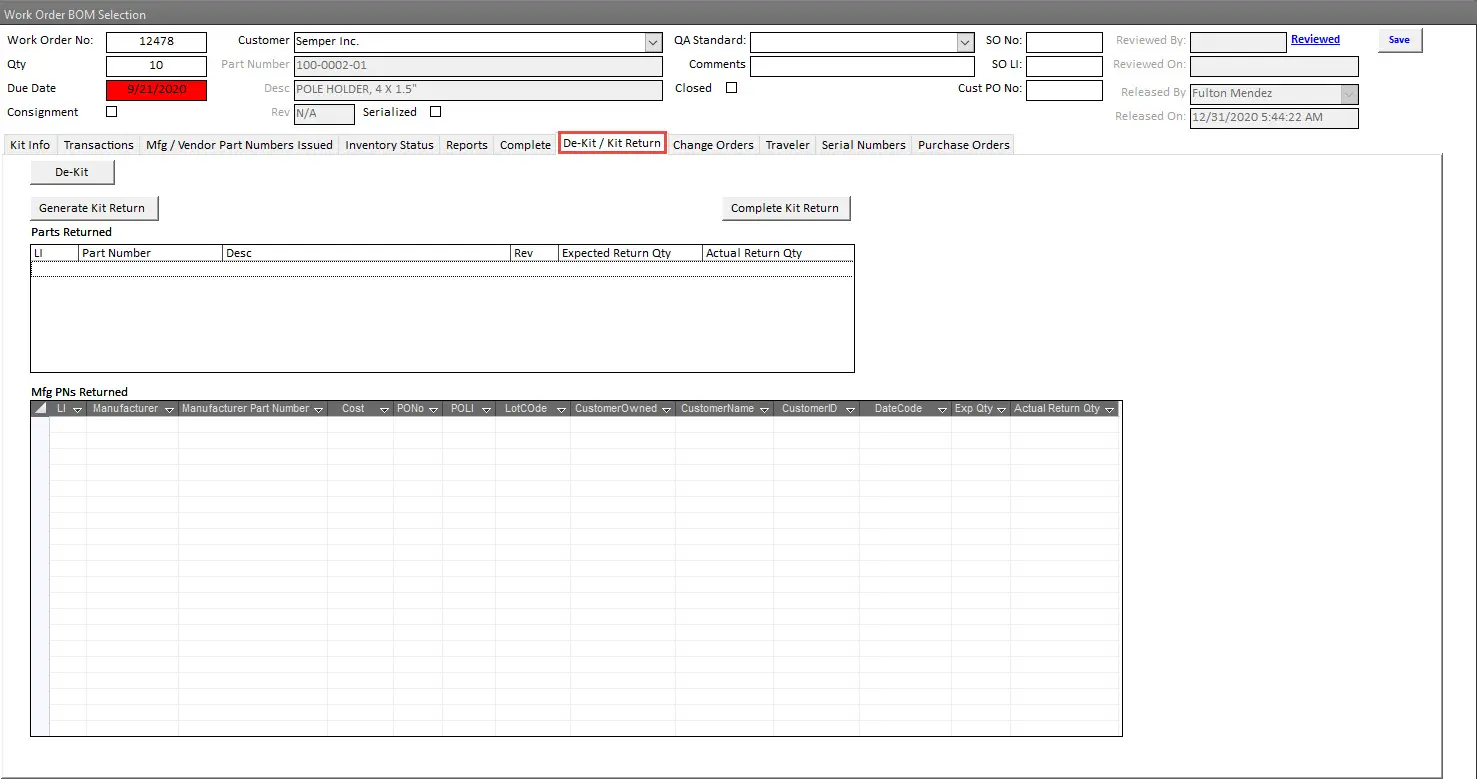

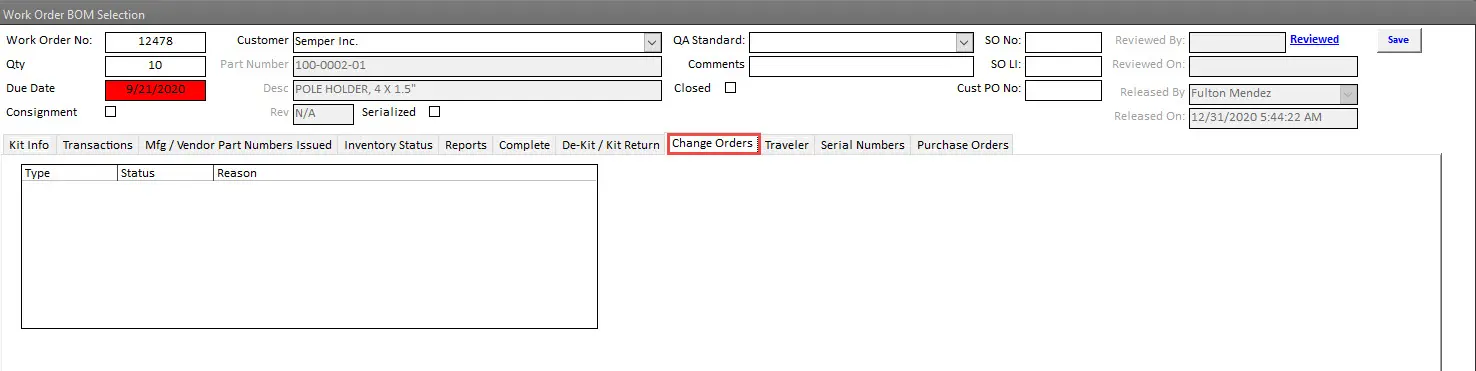

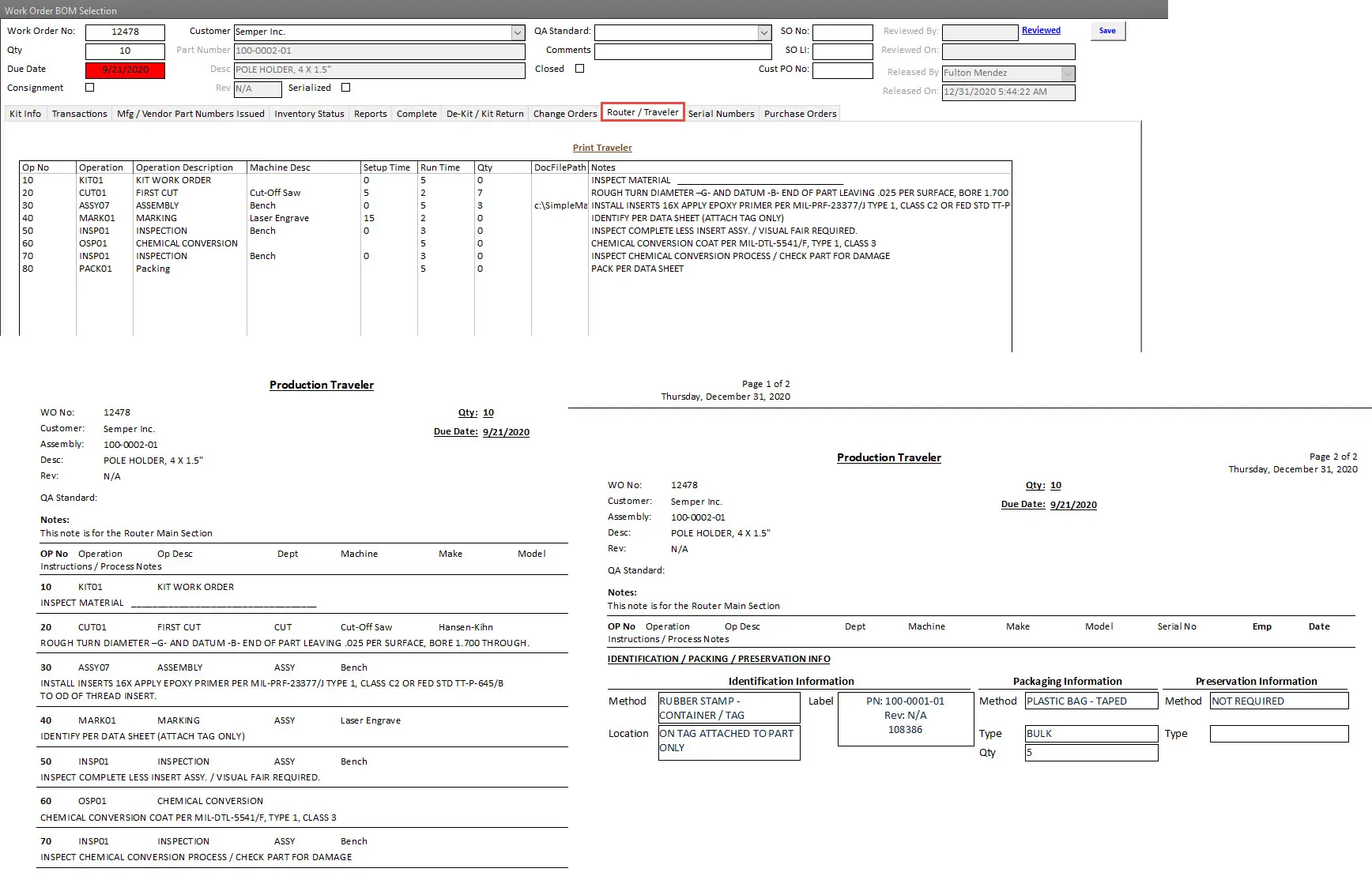

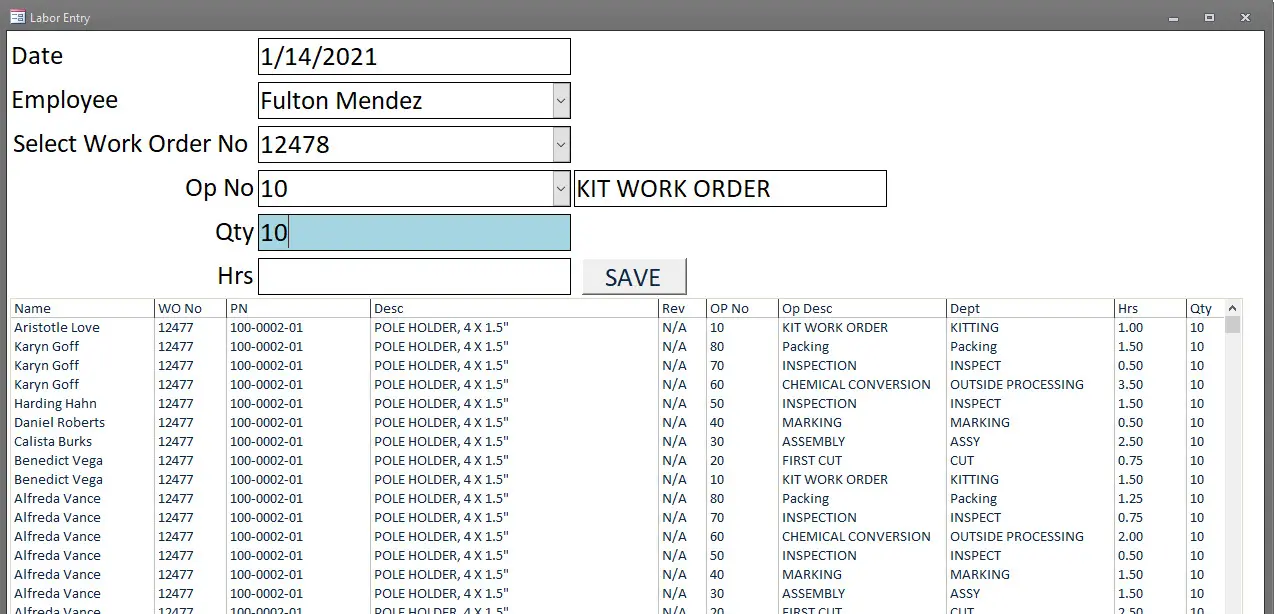

Core Work Order Features

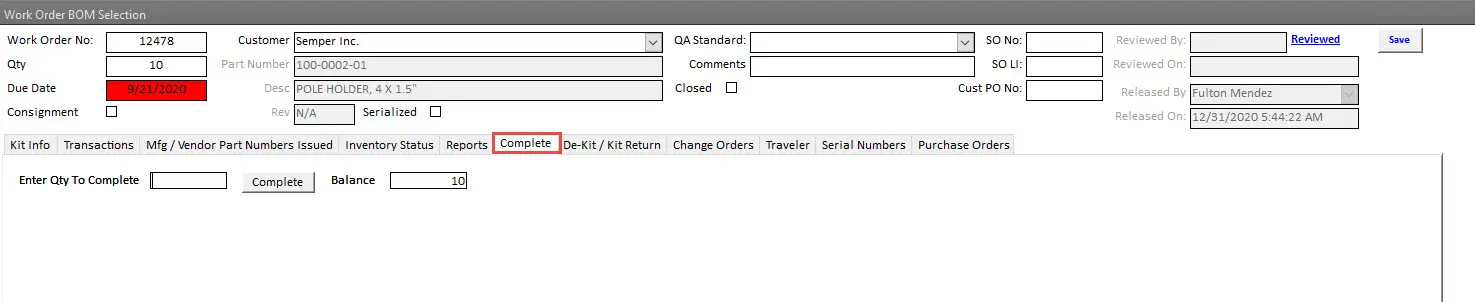

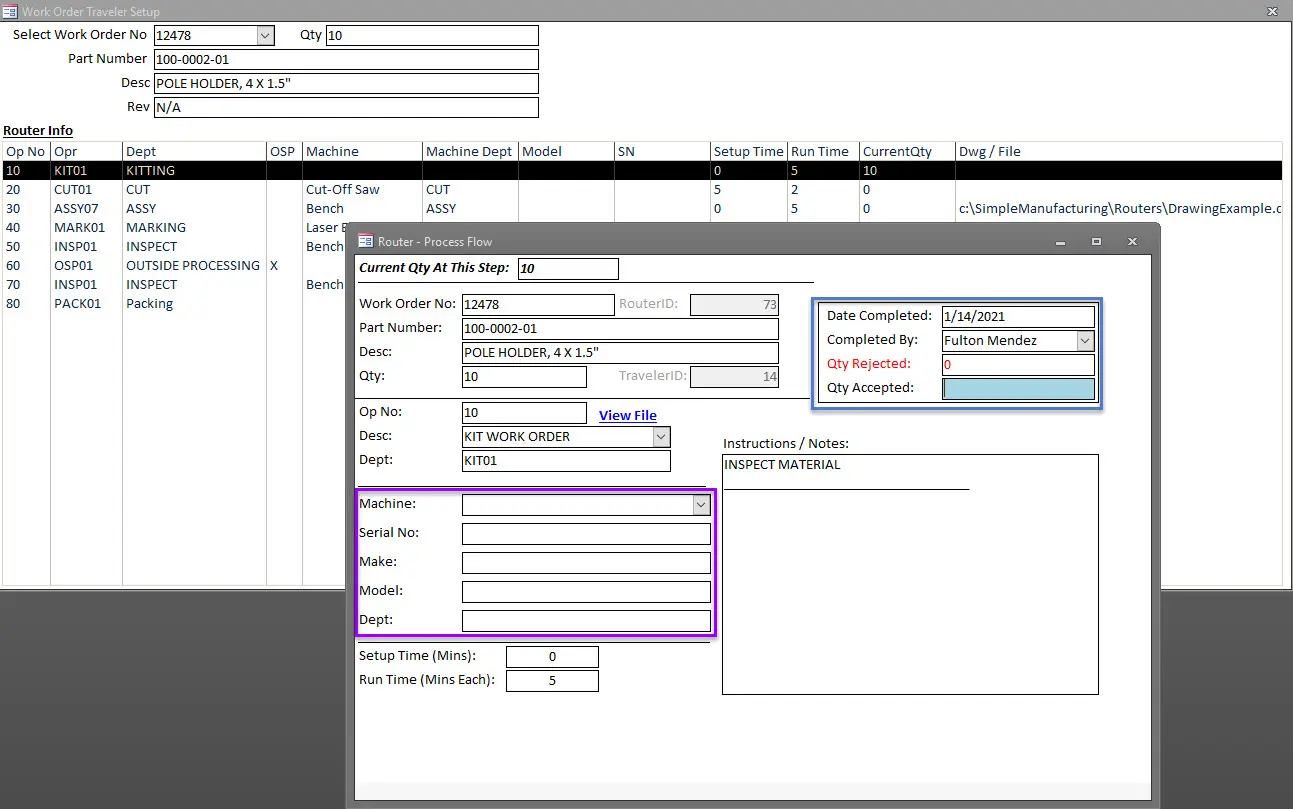

- Task details including assignment, instructions, and timeline.

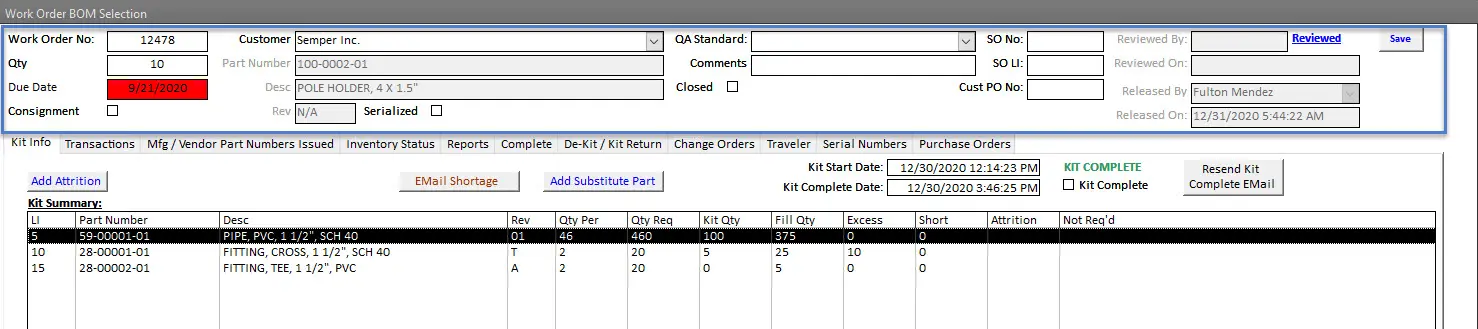

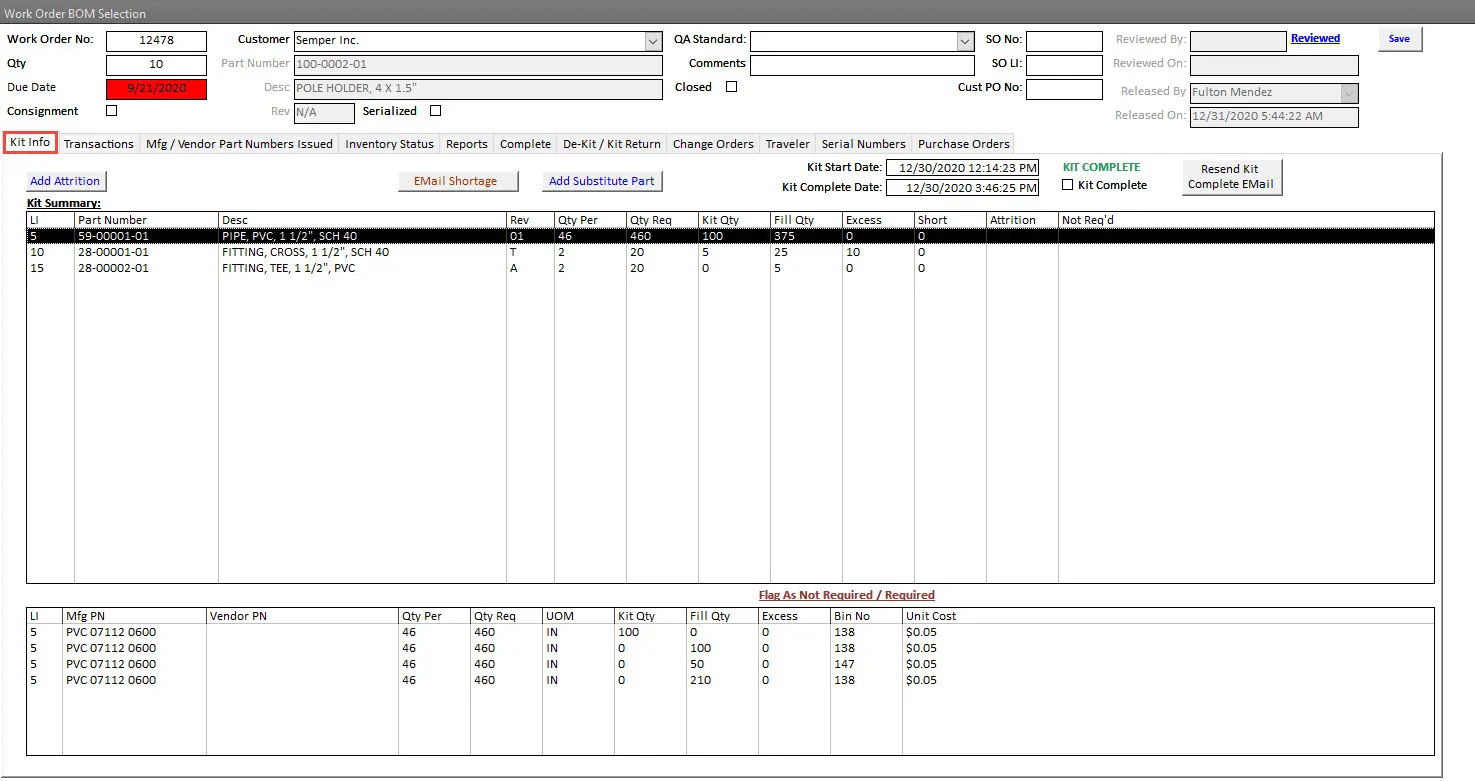

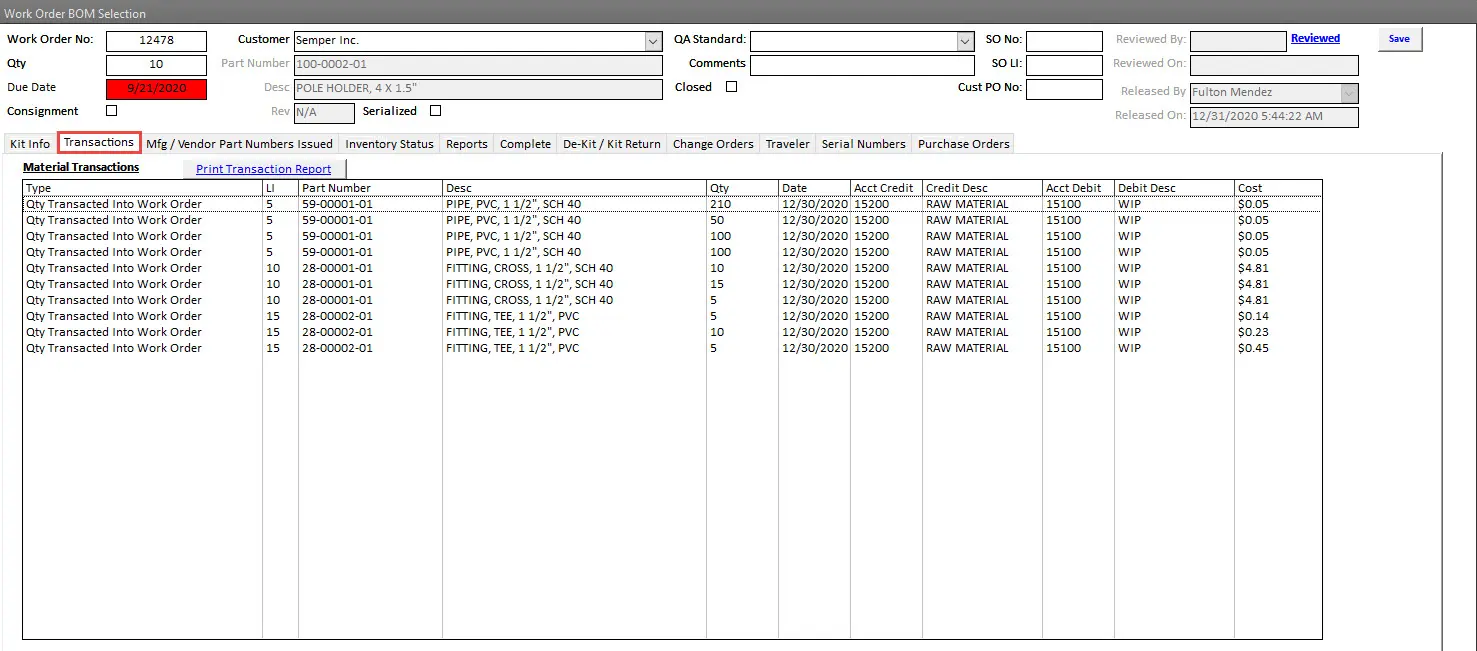

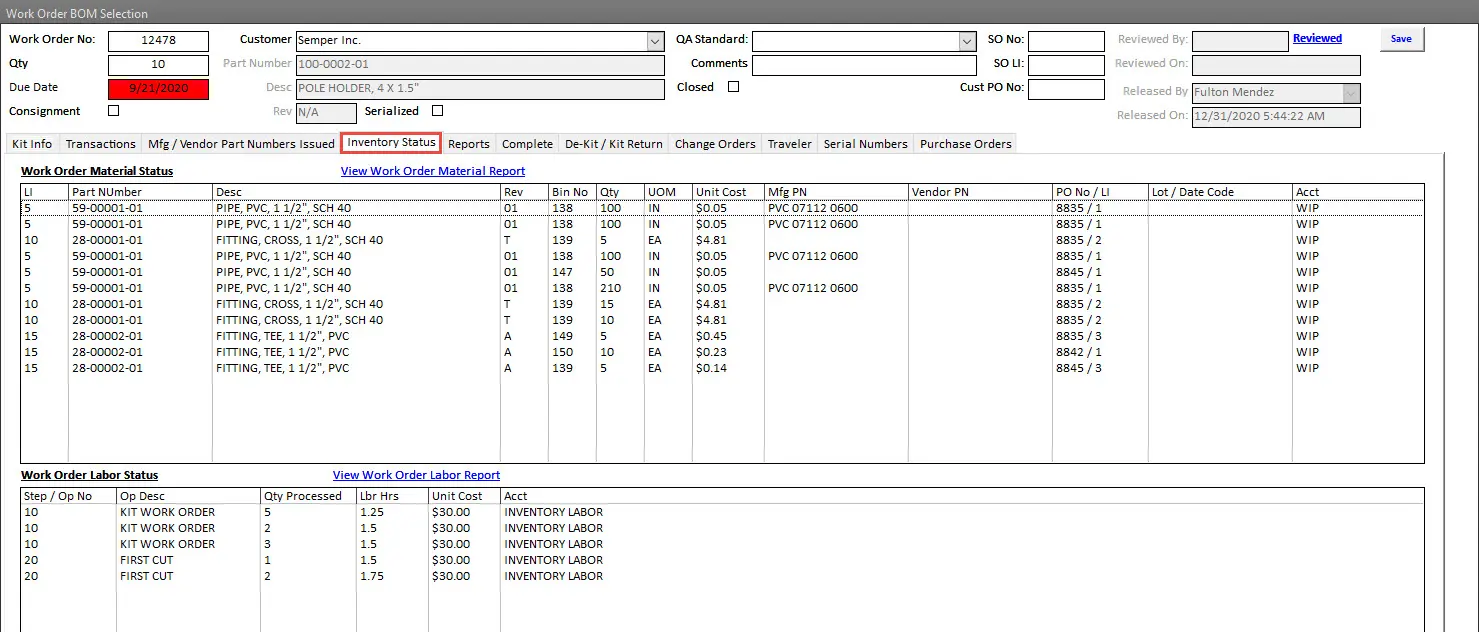

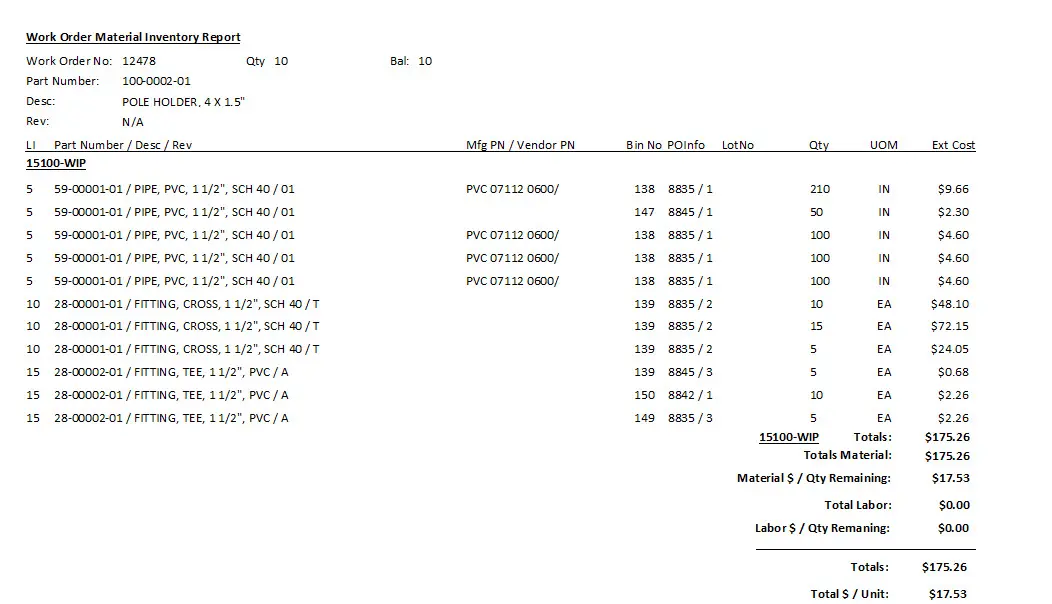

- Material and resource tracking with automatic WIP inventory updates.

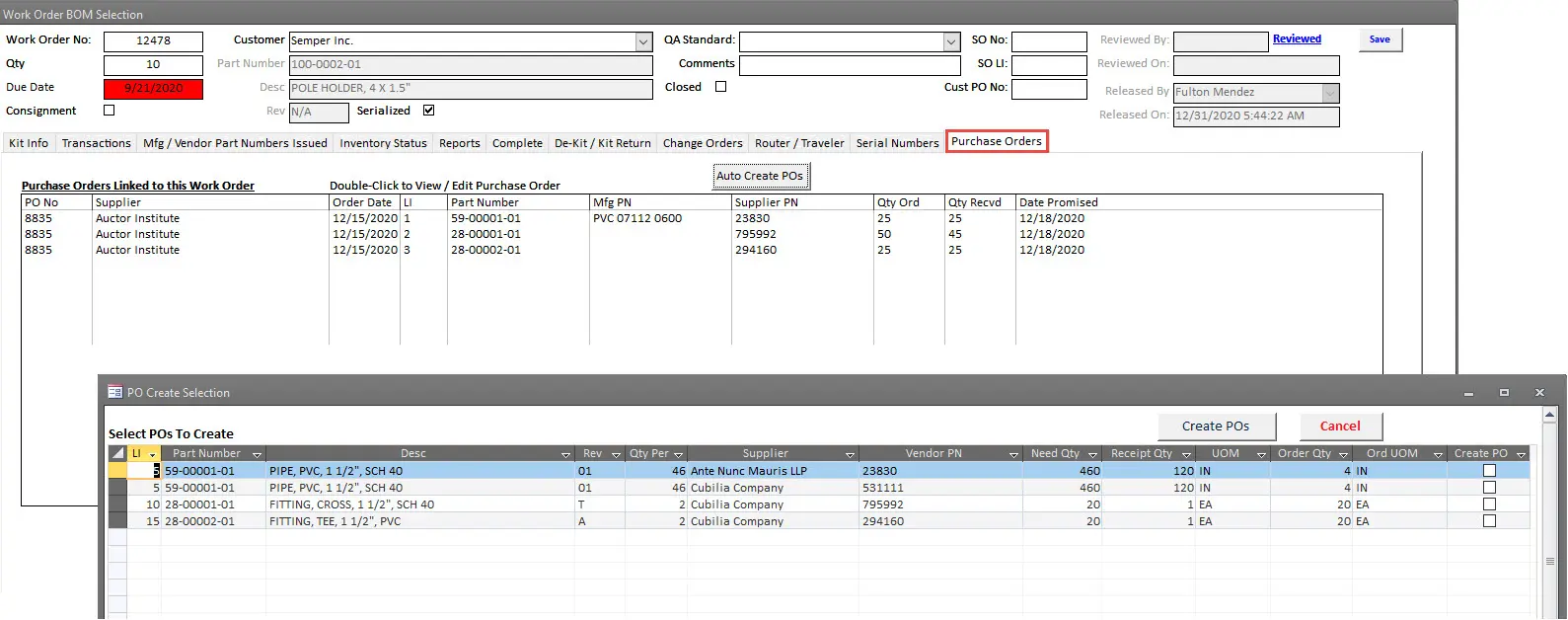

- Material shortages/excess identification and automated notifications.

- Labor and material cost tracking for accurate unit costing.

- Router, traveler, and process flow integration from BOMs.

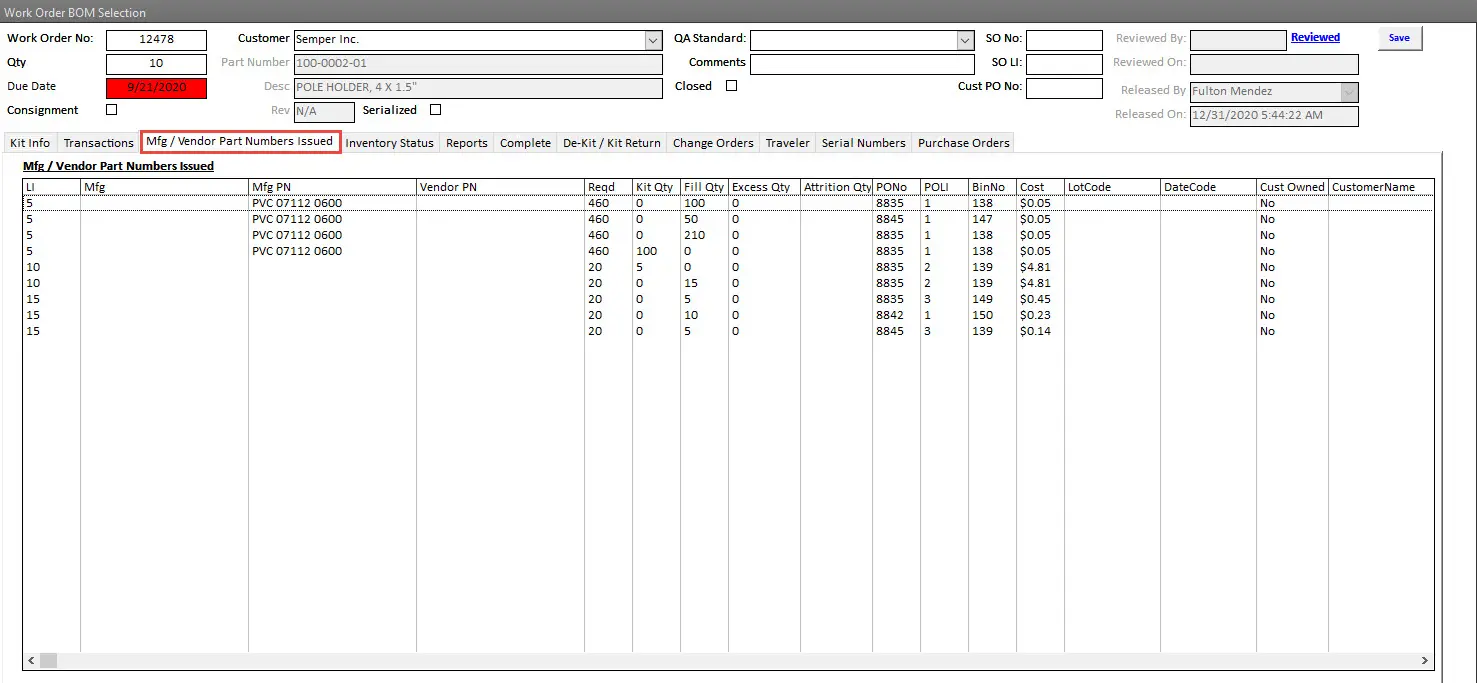

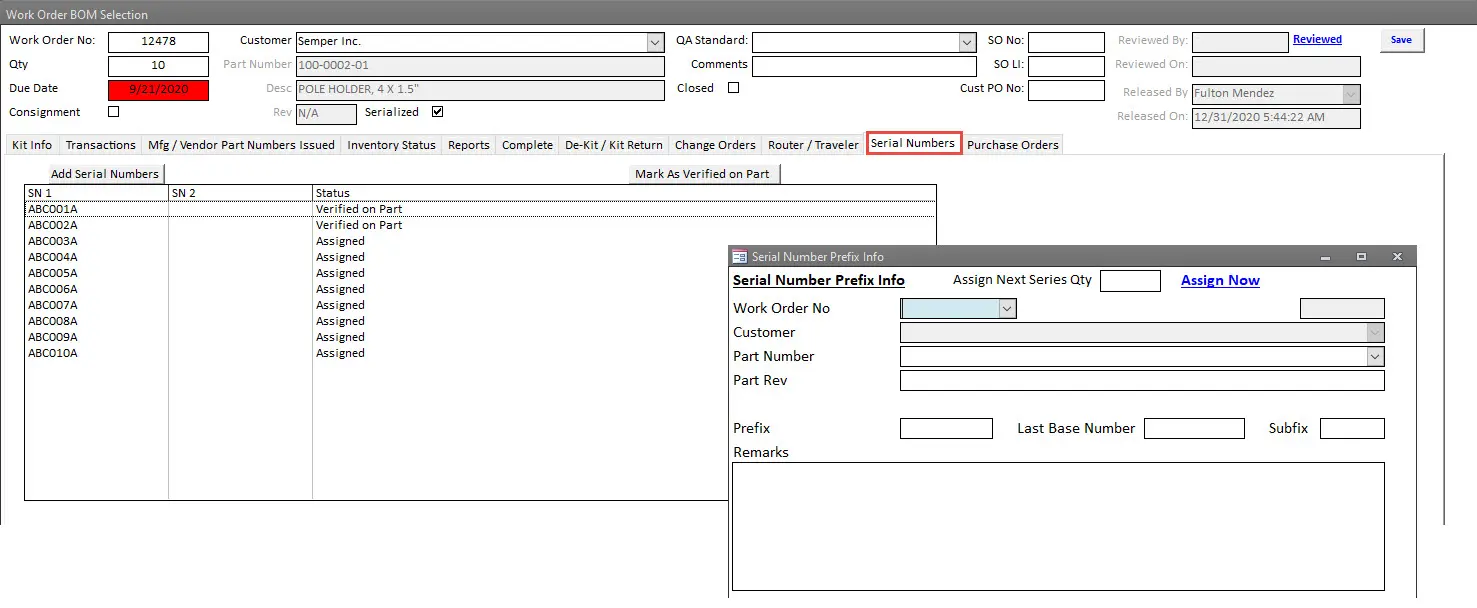

- Vendor part number tracking and serial number management.

- FIFO-based material issuing and auto-kit options.

- Email notifications for material shortages and updates.

Call for a Free Demo:

858-335-6421