Item & Part Management for Manufacturing Businesses

SimpleManufacturing™ Item & Part Management module provides a single, accurate source of item data for engineering, production, purchasing, and inventory control—improving efficiency and traceability across your entire operation.

Key Benefits

- Centralized item / part master data with revision control

- Eliminate duplicate item / part records for consistency.

- Better forecasting and cost control through real-time insights

- Improve inventory tracking and visibility across locations.

- Maintain BOM (Bill of Materials) integrity.

- Faster procurement & supply chain operations with clean data.

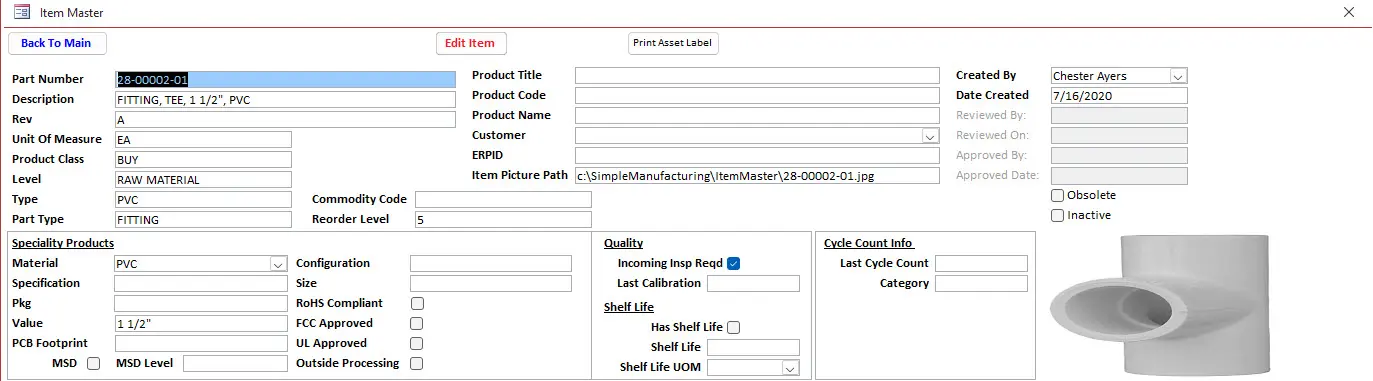

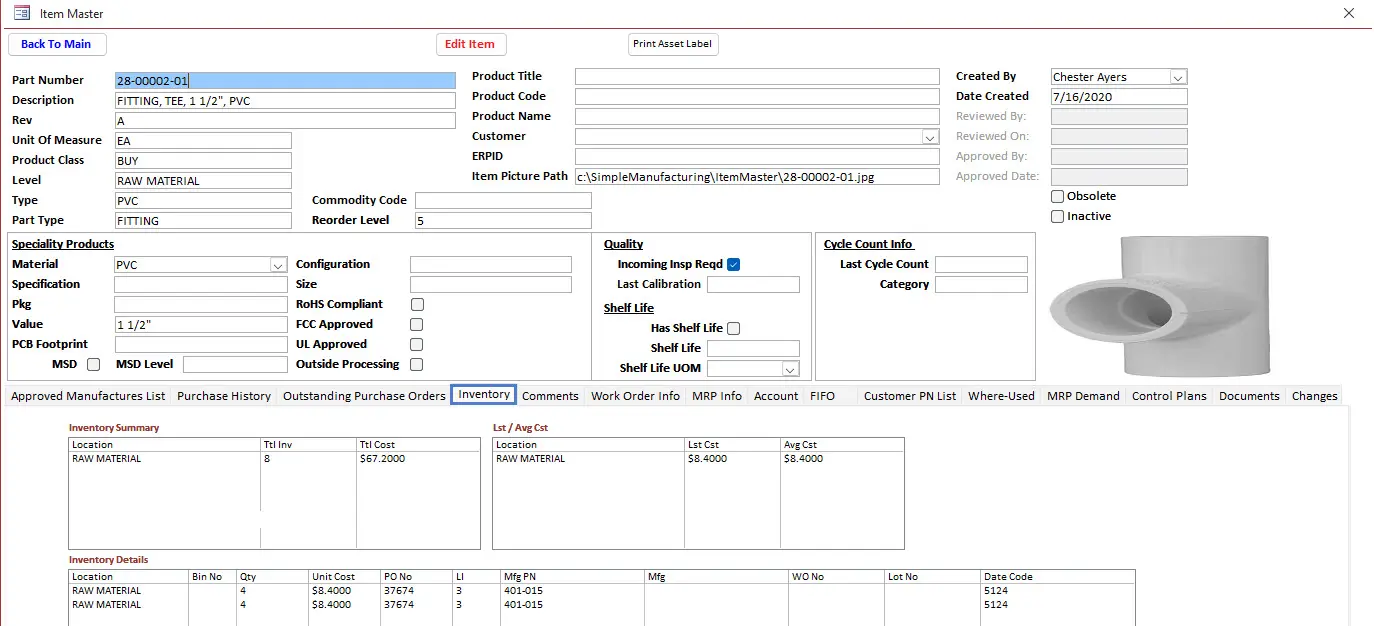

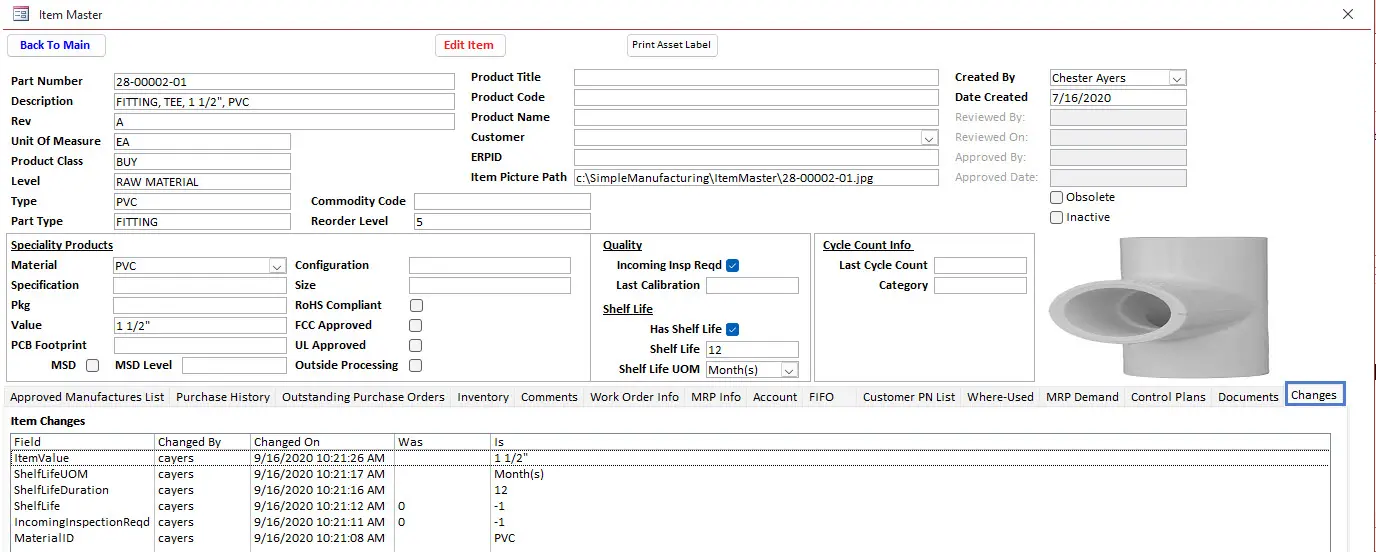

Item Master & Specialty Data Features

- Common Data:

Part number, revision, descriptions, classifications, and key specifications. - Specialty Products:

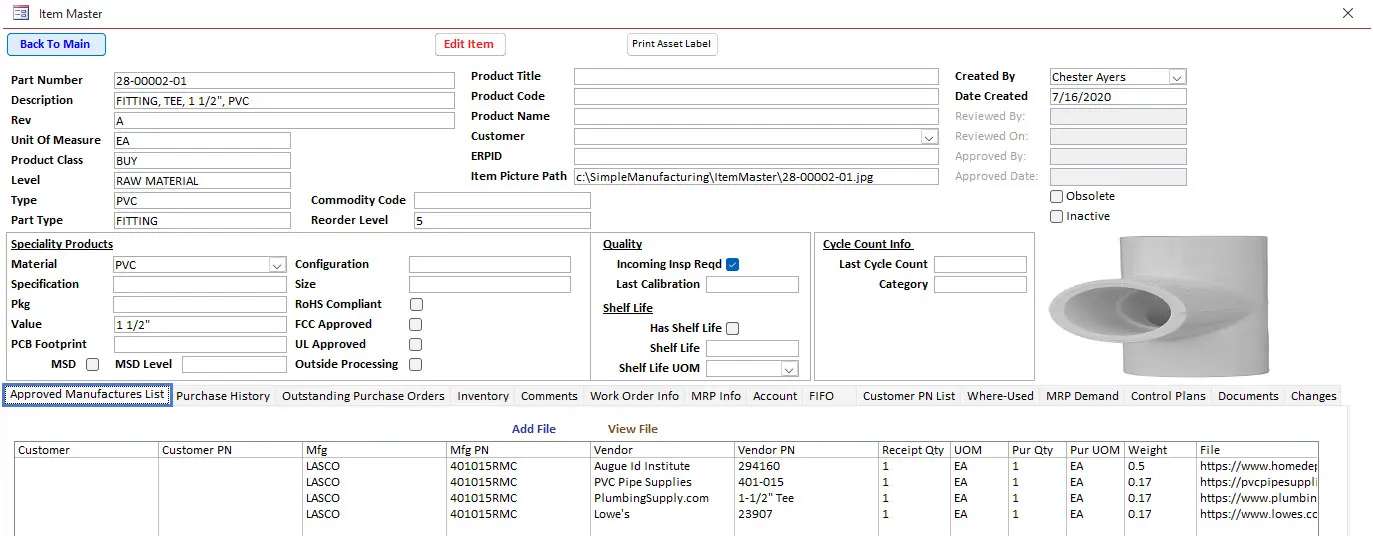

Material, packaging/layout, size, compliance standards, and quality attributes. - Approved Manufacturer and Vendor List:

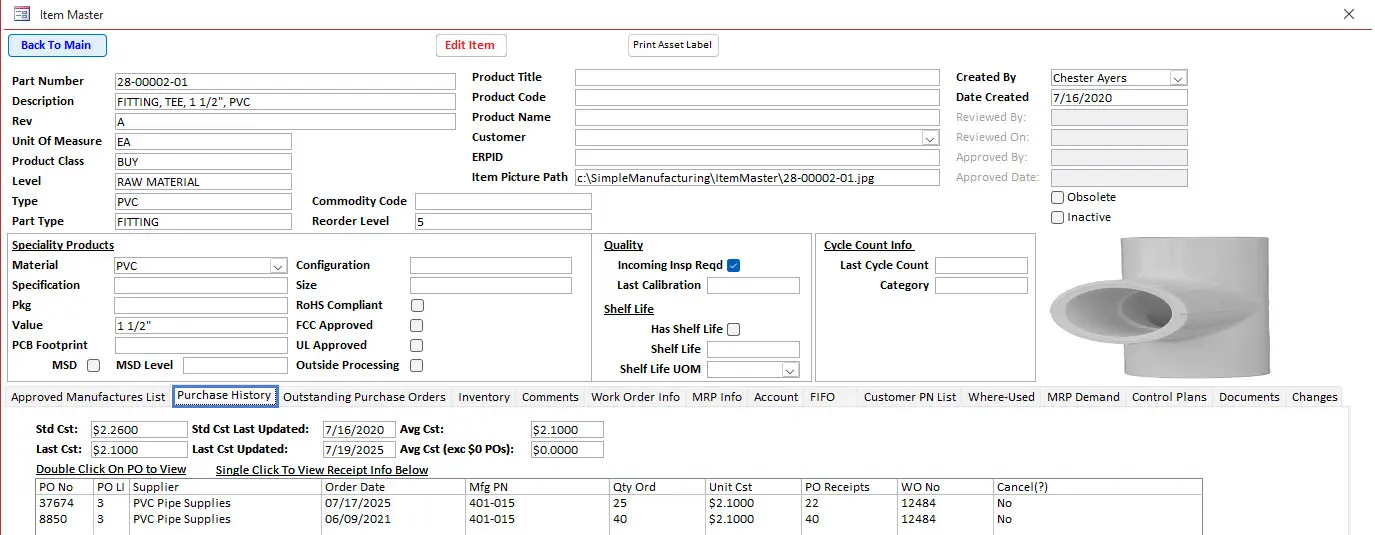

Manage AML/AVL with linked supplier details. - Purchase History:

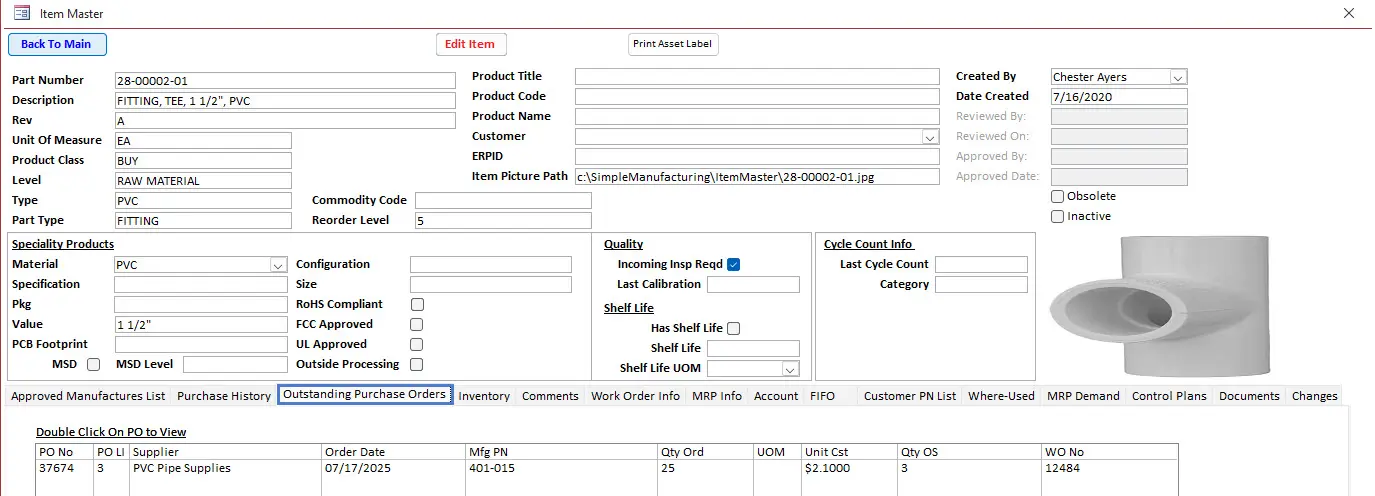

Complete record of past purchases and costs. - Open PO List:

Real-time visibility into current purchase orders. - Inventory Levels:

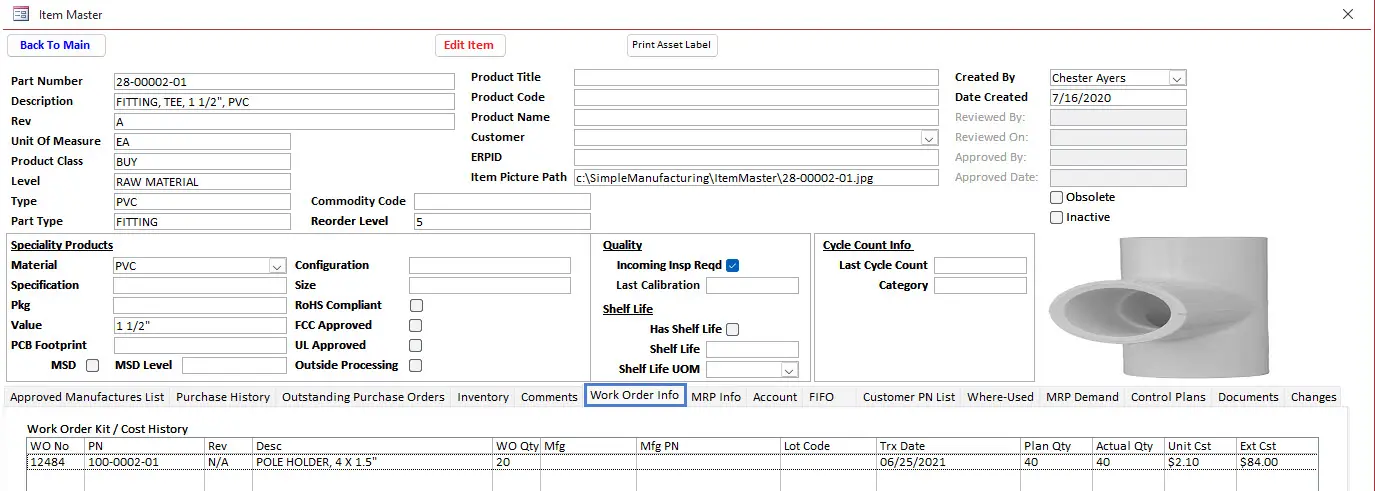

Track on-hand, allocated, and available quantities across locations. - Work Order Issue Information:

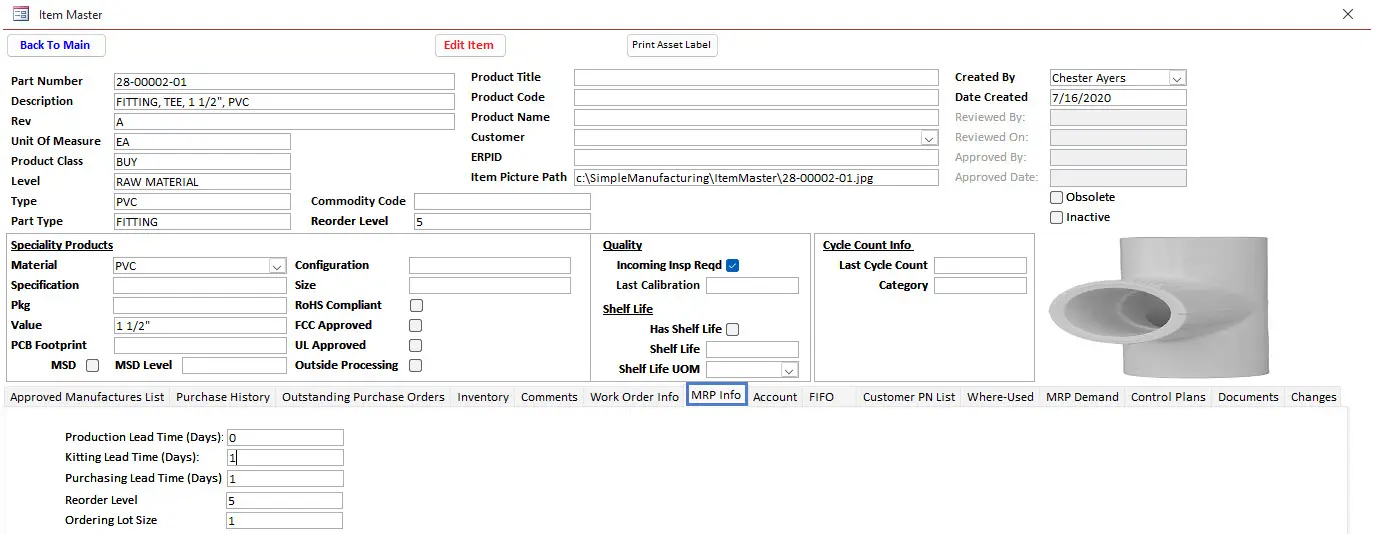

View all work orders and materials issued to production. - MRP Definition:

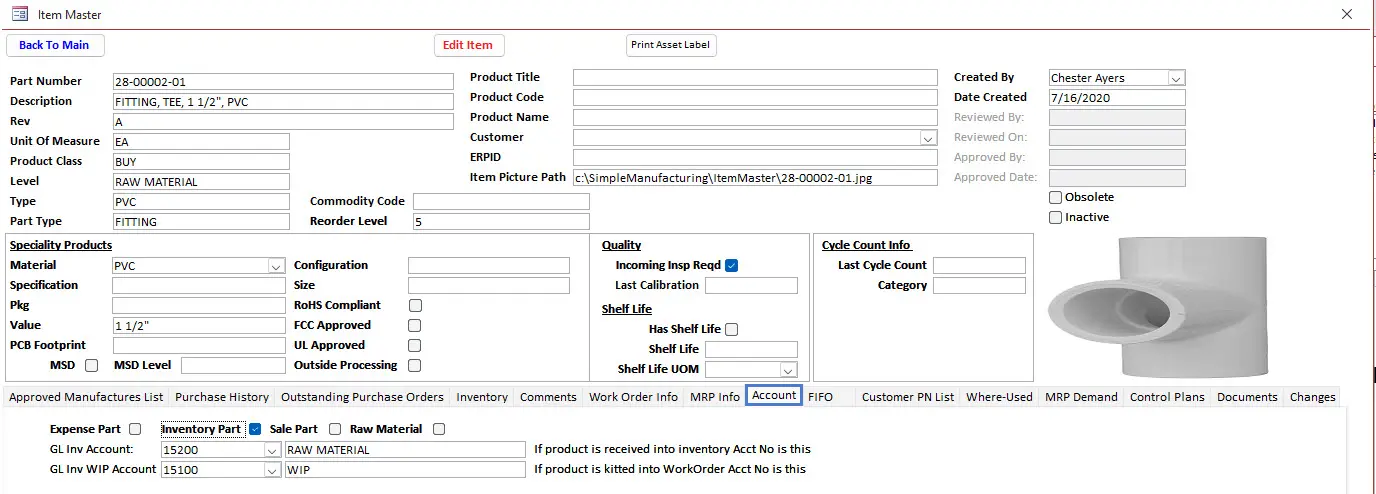

Set material requirements planning parameters for accurate demand planning. - Accounting Definition:

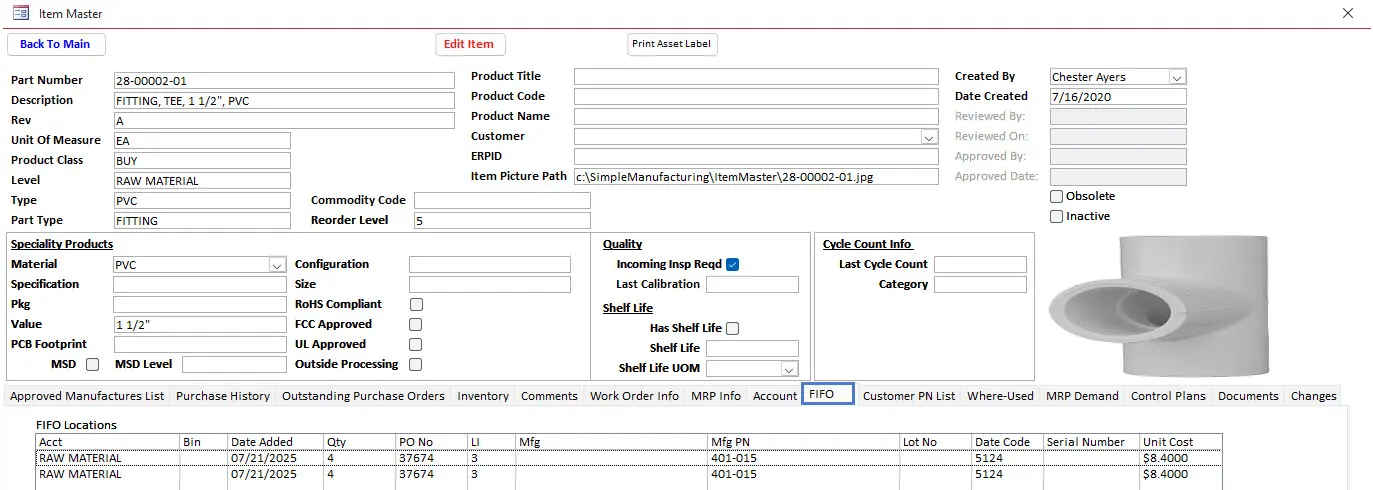

Map to chart of accounts and assign expense or inventory valuation methods. - FIFO Inventory List:

Support for first-in/first-out valuation and usage tracking. - Where-Used Information:

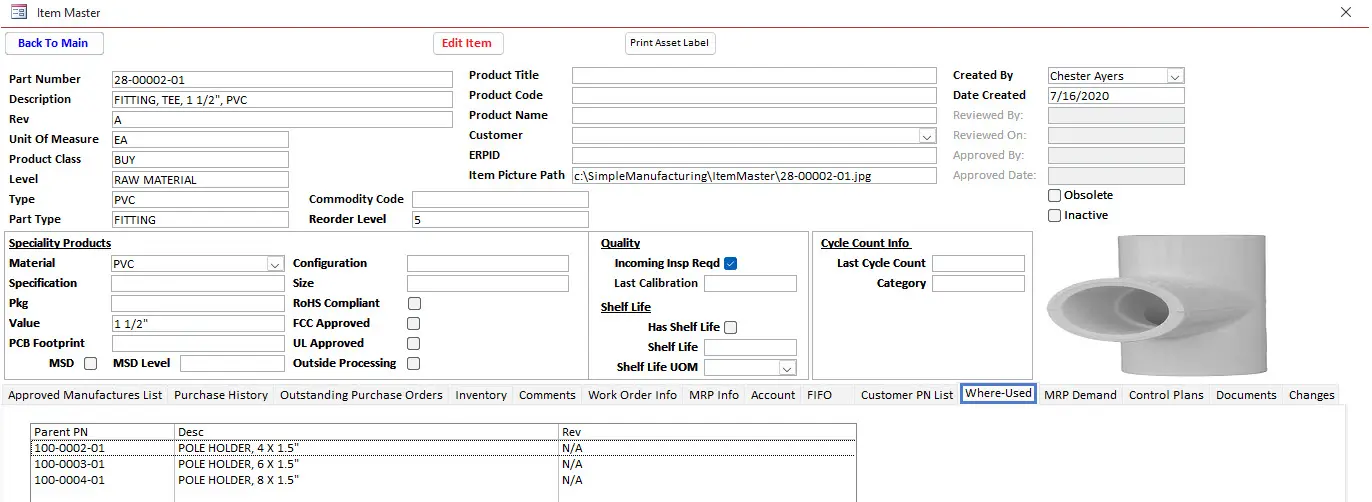

Instantly see all BOMs and assemblies using the item. - MRP Demand of the Item:

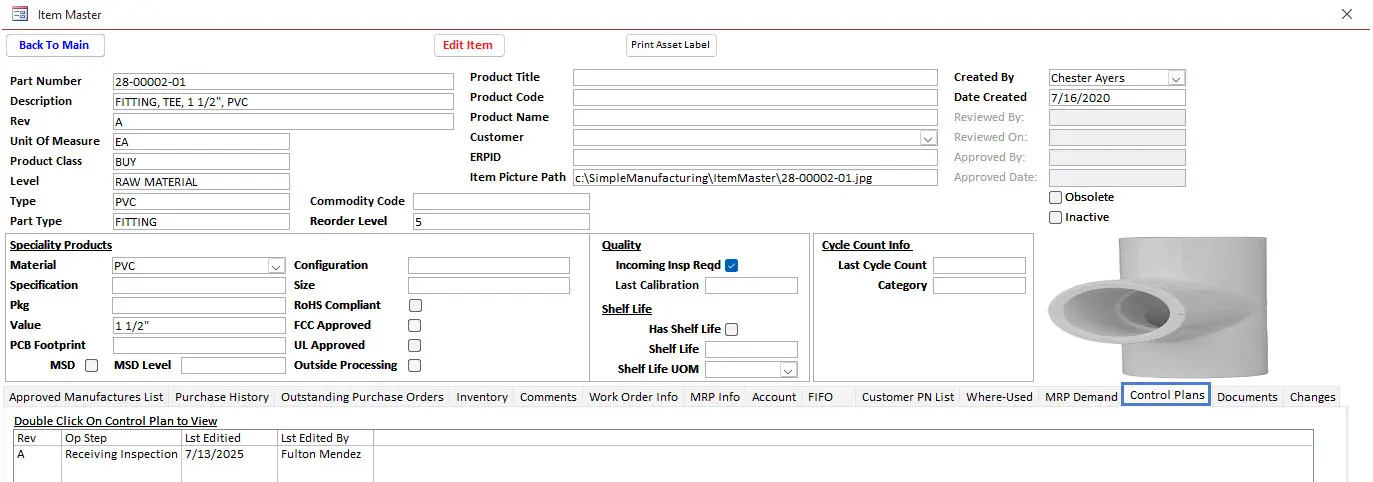

Real-time visibility into demand from planned and firm orders. - Control Plans of the Item:

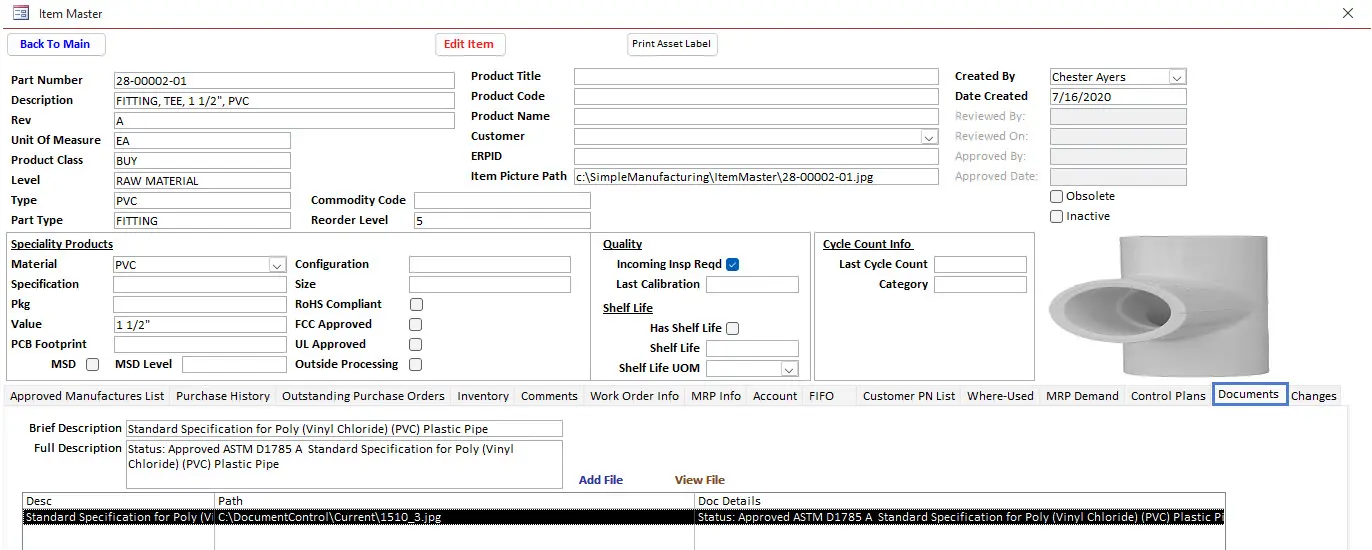

Link inspection and quality control plans directly to the item. - Unlimited Documents/Files:

Attach drawings, specifications, and certifications without limits. - Change Tracking:

Automatic audit trail of every edit—who, what, and when.