Engineering Change Order (ECO) Management

SimpleManufacturing’s ECO and Configuration Management software streamlines product changes, improves traceability, and prevents costly production errors.

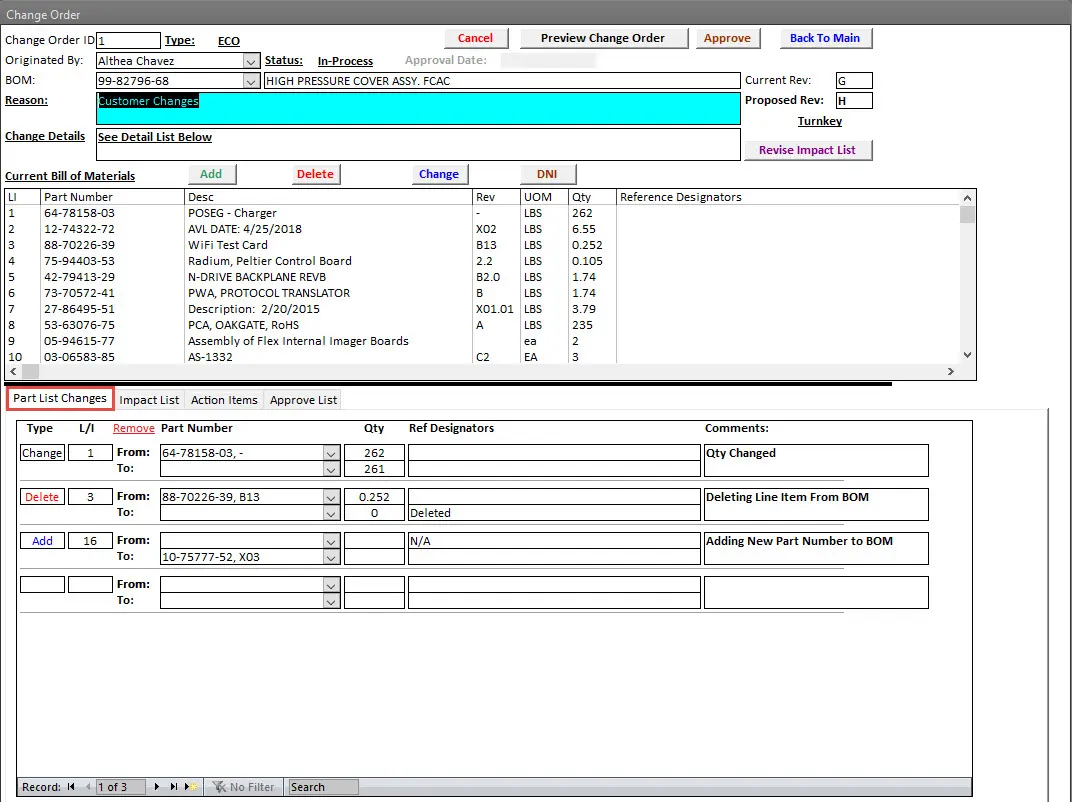

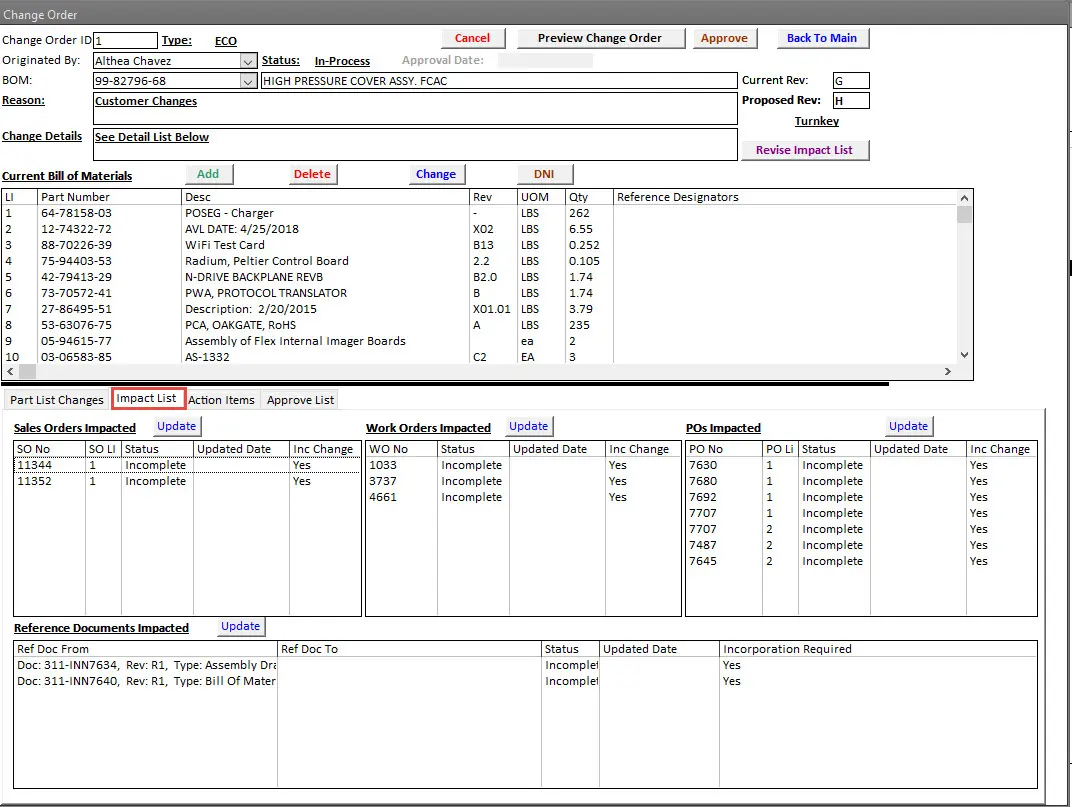

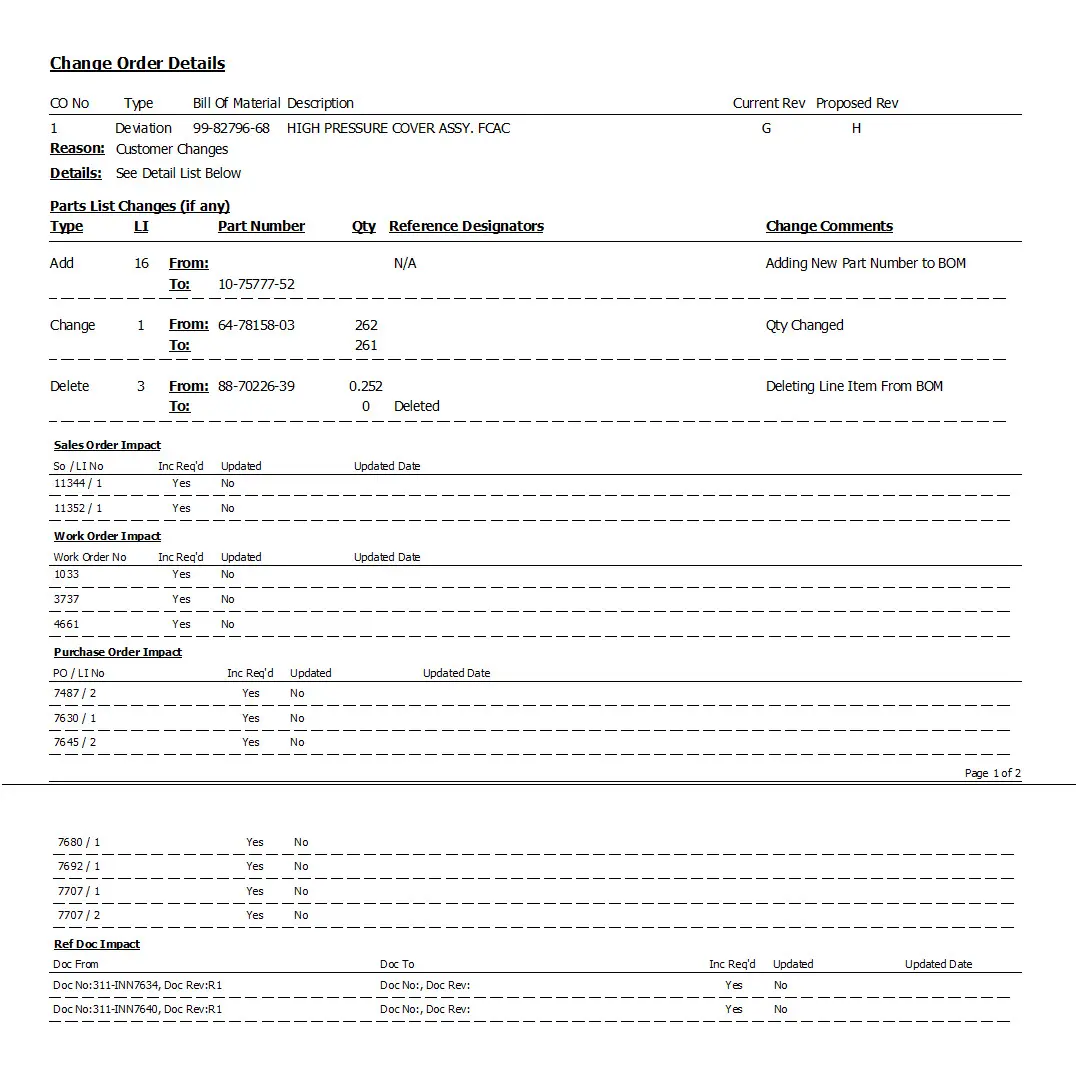

Centralized Change Control

Manage every Engineering Change Order from request to approval in one unified platform. Maintain accurate revision histories and full audit trails to ensure compliance.

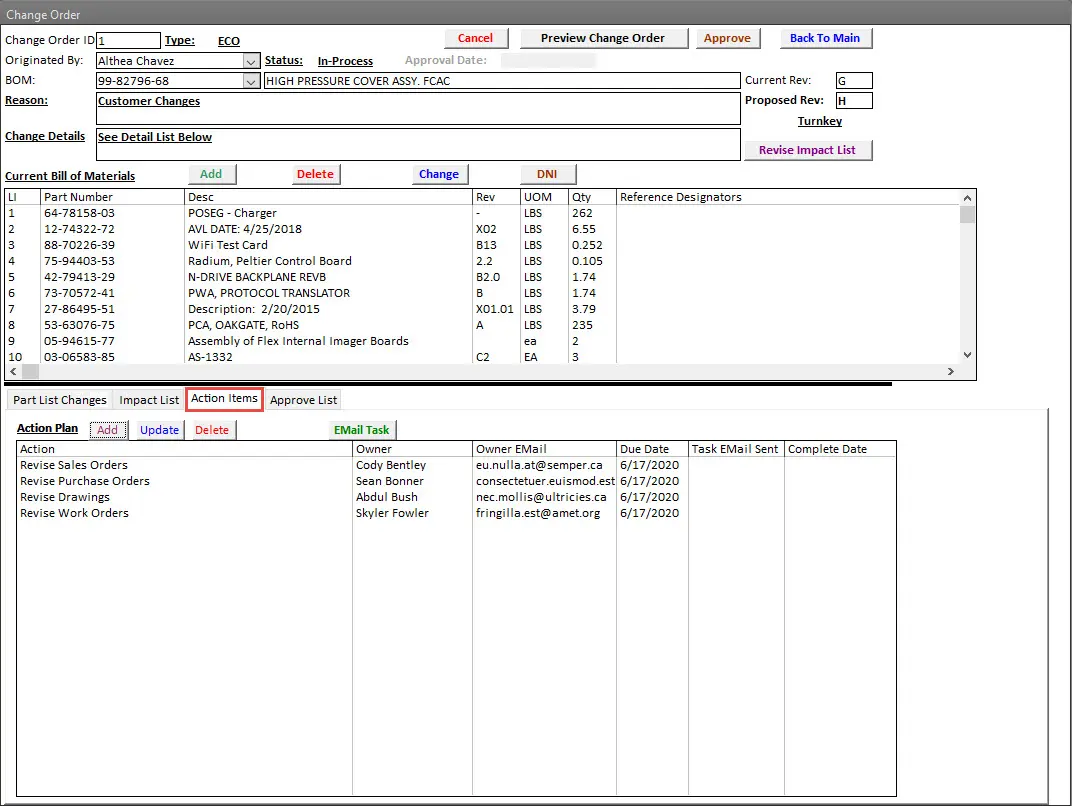

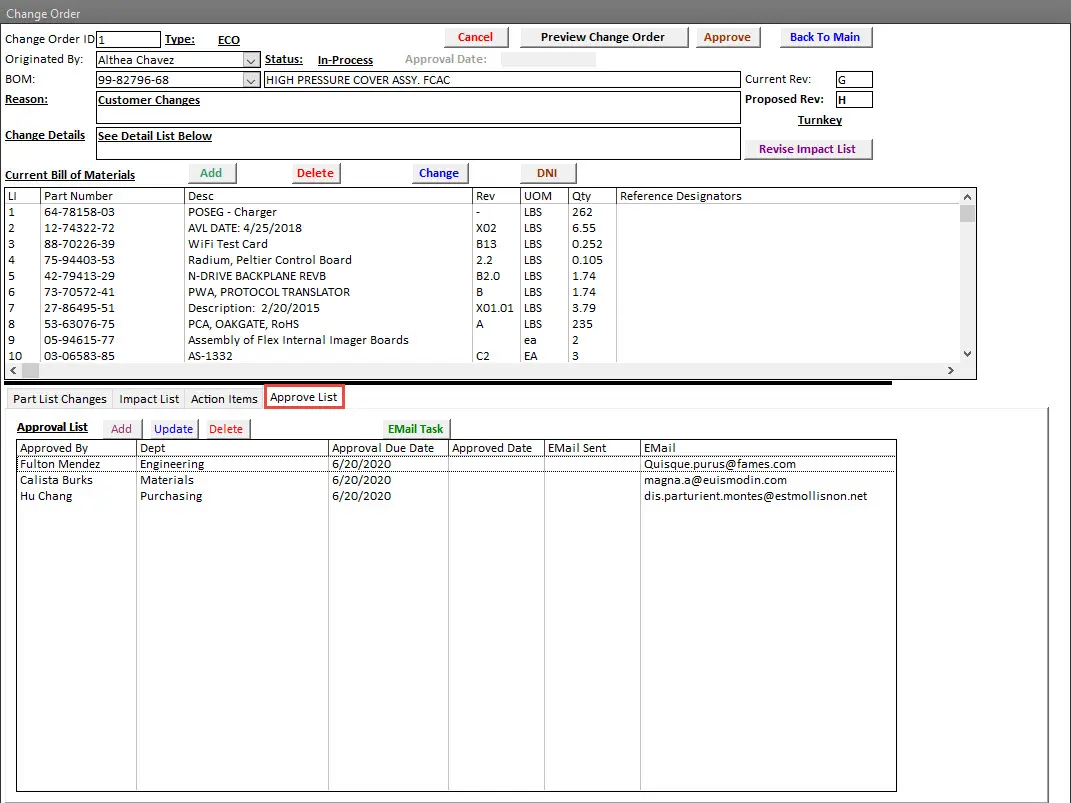

Automated Workflows

Automate notifications and approvals, eliminating manual steps. Built-in rules keep your team aligned and speed up implementation of design and process changes.

Configuration Management

Track product structures, BOM revisions, and document updates to maintain a single source of truth. Configuration control ensures that manufacturing uses the latest specifications.

- Track ECO requests, reviews, and sign-offs

- Attach CAD drawings and supporting documents

- Real-time dashboards for status and metrics

- Integration with ERP and PLM systems

Call us today: 1-858-555-1234

Request a Demo