Inventory Management for Manufacturing Businesses

Inventory Management module in SimpleManufacturing™ manages all inventory including raw material, work-in-process (WIP), finished goods, scrap, and excess/obsolete stock. It helps manufacturing businesses maintain lean inventory, improve cash flow, and meet demand reliably.

Why Effective Inventory Management Matters

- Cost Control:

Reduce storage, insurance, spoilage, and minimize expensive overstocking. - Efficiency in Production:

Ensuring right materials are available as needed prevents downtime. - Cash Flow Optimization:

Less capital tied up in unused inventory. :contentReference - Customer Satisfaction:

Having finished goods ready when customers expect them. :contentReference - Supply Chain Coordination & Demand Forecasting:

Real-time data supports better decisions. - Compliance and Traceability:

Lot codes, Serial numbers, Date Codes, Shelf Life and Expiration Dates for regulated industries.

Inventory Management Features

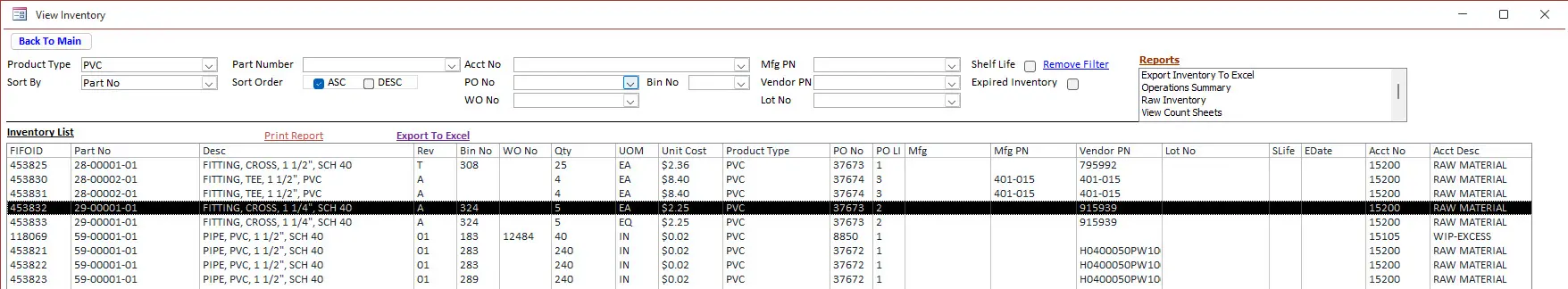

- Multiple Inventory Locations:

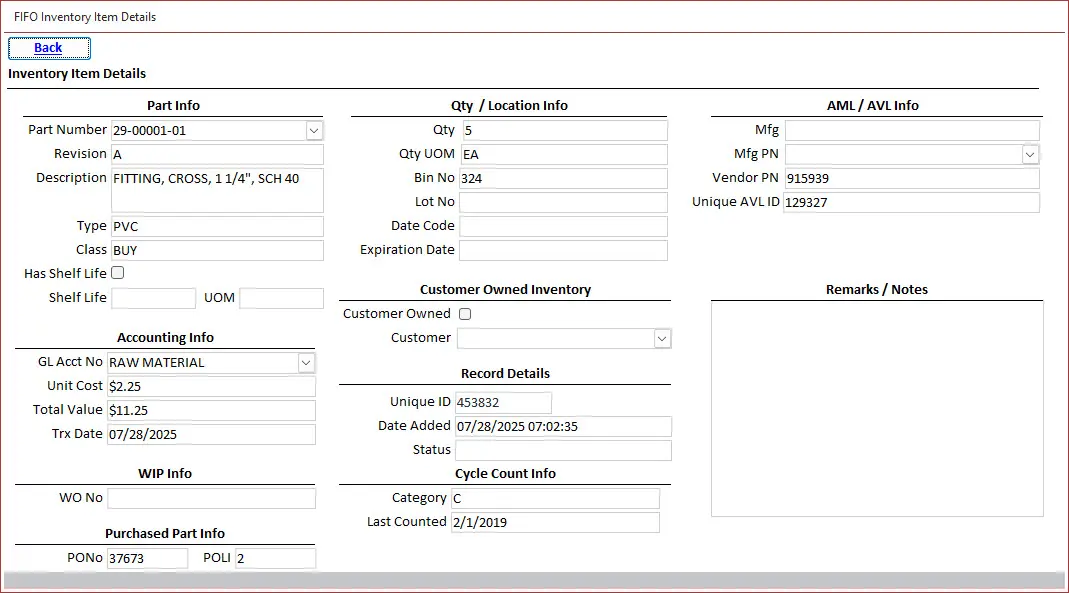

Raw material, WIP, Finished Goods, Scrap, Excess & Obsolete. - FIFO (First-In First-Out) Inventory:

Facilitates Actual costing, with standard, last, or average cost options. - Automated Transactions:

Material Work Order Issues, Transfers, Excess, Attrition, Restocking - Complete Transaction History:

Receipts, Consumption, Transfers, Adjustments. - Manual Transaction Ability:

Material Adjustments Inventory Location Transfers, with full audit trail. - Unique identification:

Date codes, Lot codes, Expiration dates, Shelf Life, Serial Numbers. - Cycle Counting Option:

Auditing process for high-risk or critical inventory items. - Real-time reports and dashboard views showing on-hand vs committed, alerts & notifications.

Want to improve your inventory visibility and control?

Contact Us Online