Guide to Order Management in Manufacturing

Ever Increasing Demands and Requirements of Customers Orders Requires Manufacturing Software to be Flexible and Adaptable.

A Guide of What You Should Expect and How to Handle It

Order Management in Manufacturing: A Guide of What You Should Expect and How to Handle It

Typical Customer Orders for Manufactured Goods

There is no industry standard for how Customers should prepare and detail an order for a manufactured good or product.

But there is some commonality most share and what you should expect to be included in orders:

-

- Customer Information:

- Customer Name

- Contact Details (phone, email, address)

- Billing and Shipping Address

- Order Details:

- Sales Order Number

- Order Date

- Delivery Date

- Purchase Order Number (if applicable)

- Product Information:

- Product Name or Description

- Product Code or SKU

- Quantity Ordered

- Unit of Measure (e.g., pieces, kilograms)

- Pricing:

- Unit Price

- Total Price (before tax)

- Applicable Taxes

- Discounts (if any)

- Special Instructions:

- Customization Requirements

- Specific Manufacturing Instructions

- Packaging Instructions

- Quality Clauses

- Specifications, Standards for Products or Processing

- Terms and Conditions:

- Payment Terms (e.g., net 30 days)

- Delivery Terms (e.g., FOB, CIF)

- Return and Refund Policy

- Authorized Signature from the Customer

- Date of Approval

- Approval and Signature

- Customer Information:

Now Lets Look At these in Detail

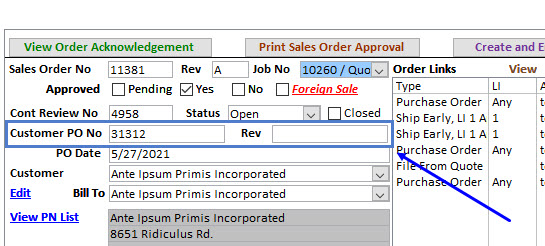

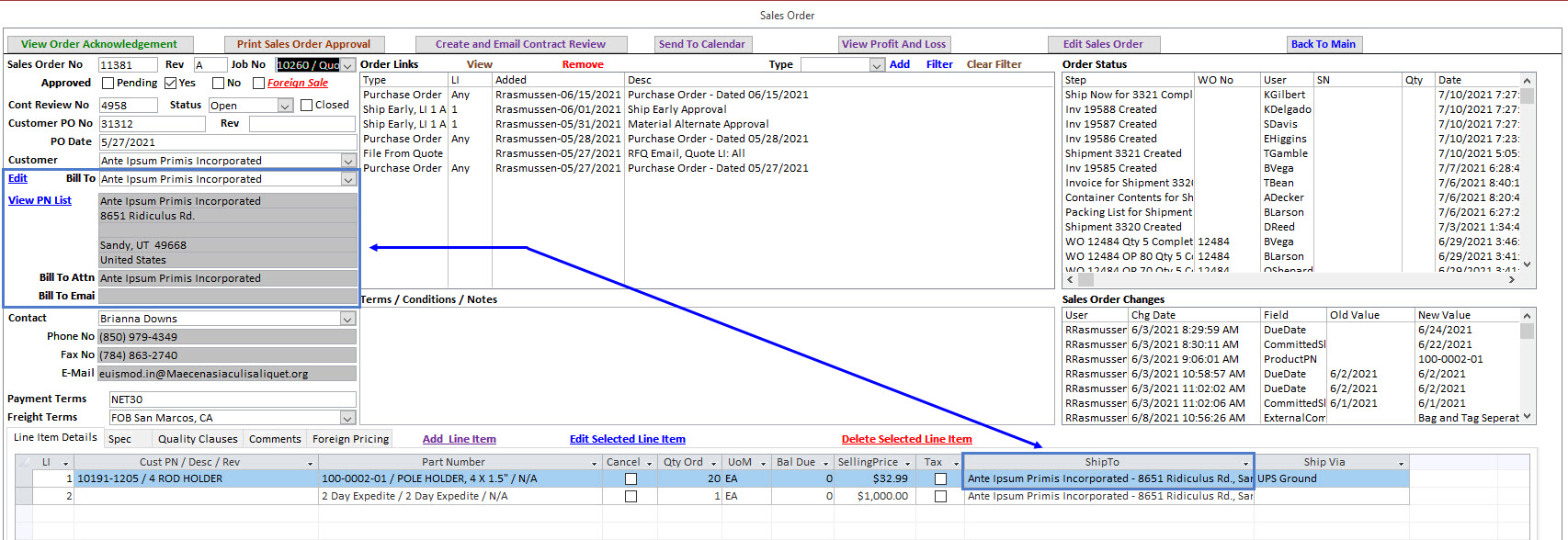

Customer Purchase Order Number and Revision

Whenever interacting with Customers regarding their orders, they will want to know what Purchase Order number is being discussed. In addition, some customers revise purchase orders using either an alpha revision level or a revision date. Business Software, like SimpleManufacturing™, must include a location to store this information – Purchase Order Number and Revision Level. It is recommended that it is not simply stored in a “note or comments” section that will be expanded on with other pieces of information. Storing such information in a “note or comments” section makes searching and finding it expeditiously difficult. It should go without saying that Business Software, like SimpleManufacturing™, should have its own unique internal Sales Order number, separate from the Customers Purchase Order number.

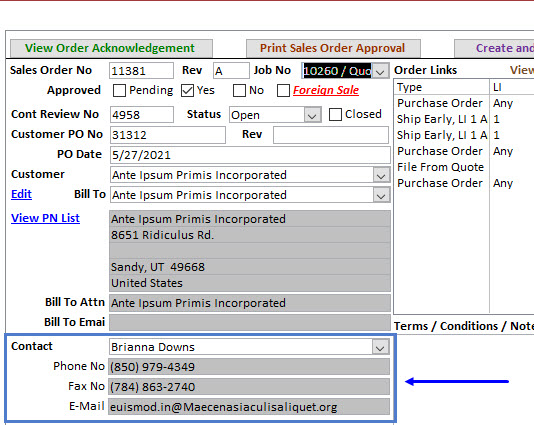

Bill To and Ship To Information

Business Software, like SimpleManufacturing™, should be able to identify Customer Bill To information. Bill To information is critical for the Accounts Receivables process. It is recommended that the Business Software allow multiple Bill To options to be added per Customer. It is not uncommon for larger Customers to submit Purchases Orders having different Bill To information.

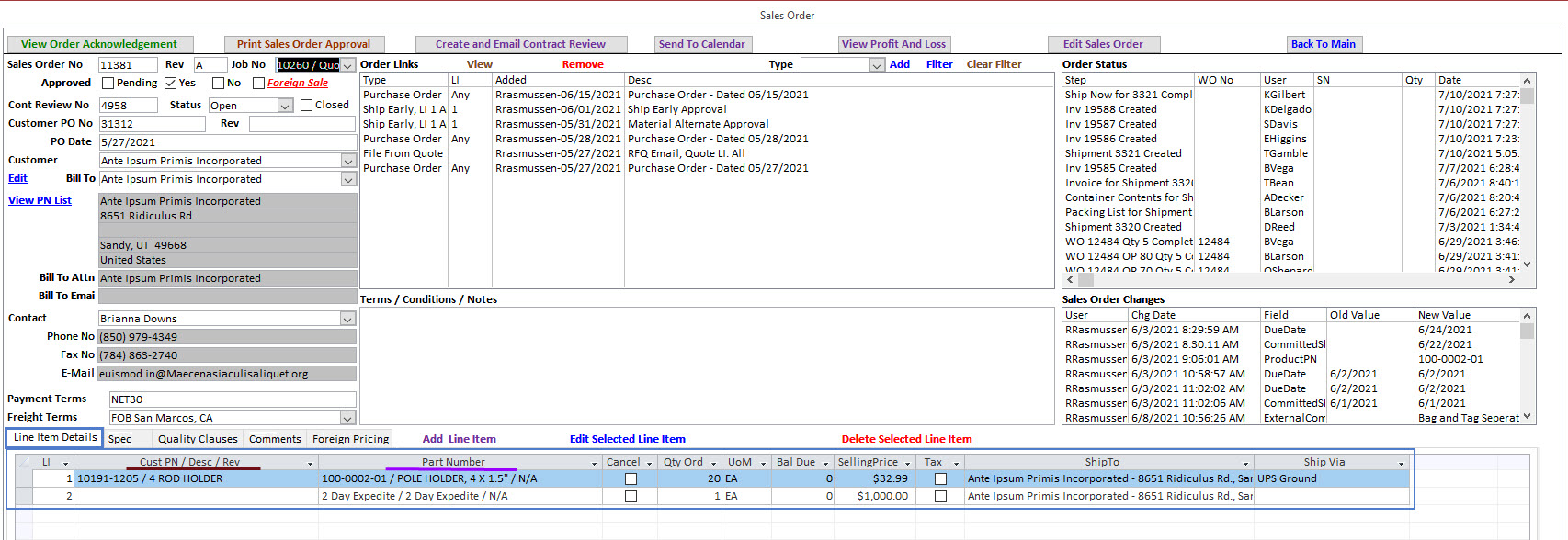

Ship To information is also an essential part of all Customer Purchase Orders. As the name would imply, the customer identifies where they expect the product to be shipped to and perhaps the logistics provider and delivery speed. Again, this is essential information that must be added to the Order or Sales Order within any Business Software.

In many cases, customer Purchase Orders now identify different ship-to locations for each line item ordered. But, again, Business software, like SimpleManufacturing™, must be able to replicate the ship-to locations within each line-item order. Therefore, it is crucial to ensure that multiple ship-to locations can be added for each Customer.

In summary, Business software must include the ability to include multiple bill and ship-to locations for each Customer within the Customer Management module.

Customer Contact Information

Business Software, like SimpleManufacturing™, should be able to manage Customer Contact information. It is common to have multiple contacts identified per Customer. It is typically identified by Job Titles to Functional Group, and common to have contacts from Sales, Accounting, Engineering, Quality Assurance, etc.

Many Customer Purchase orders have a contact identified should there be any issues, questions, or concerns about the Purchase Order. Again, having the contact information identified within the Business Software Sales Order saves time should they need to be contacted.

Identification of Purchased Goods or Services

Customer Purchase Orders typically include Line Item, Part Number, Revision Level and Part Description, Service Description, Quantity Ordered, Unit of Measure, and Unit Price. At a minimum, Business software, like SimpleManufacturing™, must include fields to replicate this exact information within its Order or Sales Order line items.

Customer Part Number and Internal Part Numbers

The use of internal part numbers within manufacturing and service companies is a common occurrence because, for the most part, there are more advantages to doing so than not. Yet many Customer Purchase orders list their part numbers to manufacture. So, it is also essential in any Business Software to identify the Customer Part Number, Description, and Revision Level along with the Internal Part Numbers, Revision levels, and Descriptions the manufacturer has created. The manufacturer can now manage all the necessary data, part numbers, and information to fulfill the Customer’s order.

A common practice of many manufacturing or service companies is to include the Revision Level at the end of a part number because they lack a separate Revision Level field within their Business Software. This approach causes many issues and an overall approach that should be avoided. Business Software, like SimpleManufacturing™, must have a separate Revision Level field for Part Number Information.

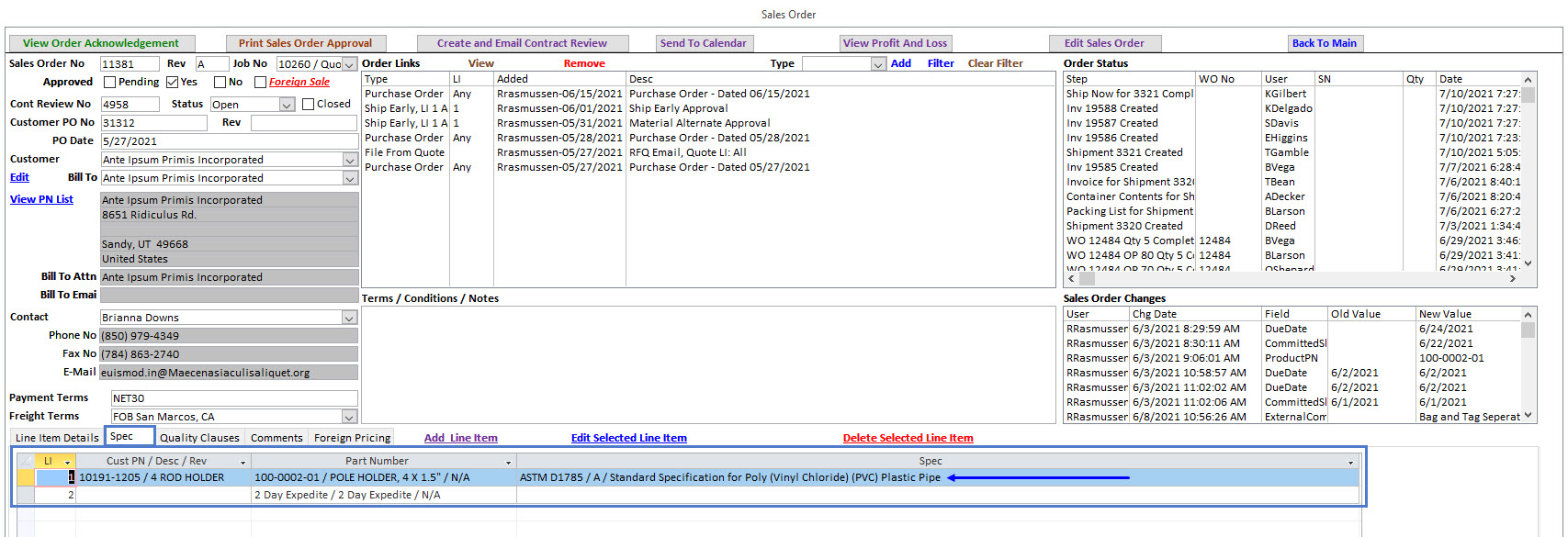

Specifications, Standards, and Other Industry-Specific Documents

The domino effect of product demand can be best explained by our Military ordering 35, F-18 Hornets. No single company builds airplanes in their entirety. It has been estimated that producing a single F-18 Hornet airplane involves a supply chain that includes tens of thousands of companies and hundreds of thousands of people. For a supply chain to be effective, all businesses within the chain need to understand the impact of their actions upon those businesses both up and down the chain.

Passing down product requirements in the supply chain is a common occurrence. To that extent, whenever a Customer Purchase Order identifies the Specifications, Standards, and Industry Specific Requirements for the product or service being purchased, any Business Software, like SimpleManufacturing™, must be able to include these within the Order as well.

In addition, the Business Software should be flexible enough to include these requirements at the line-item level, as different products ordered may have different specifications or standard requirements. Documenting these requirements within the Order is challenging if this flexibility is unavailable.

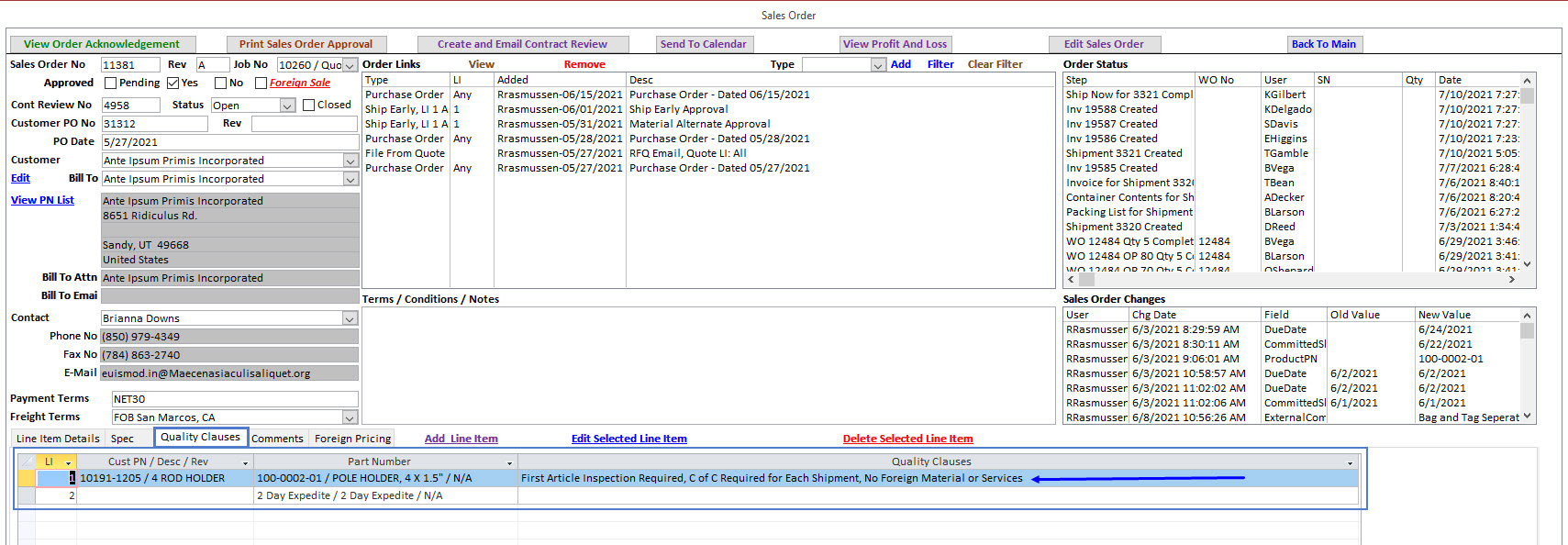

Quality Clauses

Like Specifications, Standards, and other Industry-Specified Documents, Quality Clauses are also added to Customer Purchase Orders. Unlike a standard, it is common practice for businesses to create their own set of Quality Clauses. These Quality Clauses can then be referenced within their Purchase Orders, and it is up to the Supplier to obtain the list and understand the requirements of such Quality Clauses.

Any Business Software, like SimpleManufacturing™, should have separate fields to capture the Quality Clauses passed down from the Customer Purchase order. In addition, it is recommended that those fields are included in the line items as it is not uncommon for each product ordered to have different Quality Clause requirements.

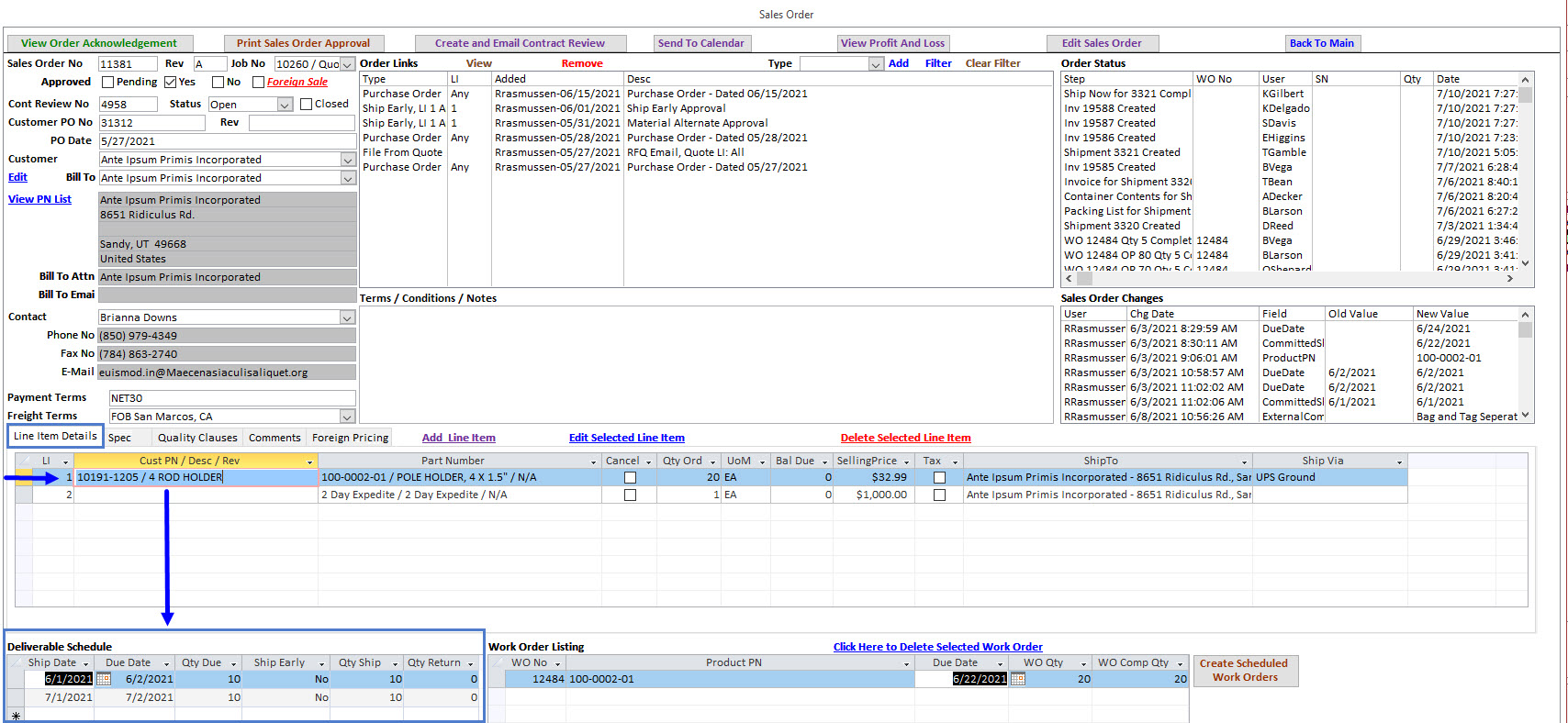

Delivery Schedules

Blanket Purchase Orders reduce administrative time by creating fewer Purchase Orders for a larger quantity of products, expecting the delivery of those products to be in smaller quantities over a more extended period. In many cases, the delivery schedule and quantities are unknown beforehand. Customers will submit specific quantity and Delivery Date demands as time evolves. This concept is challenging for Suppliers as they must balance having products available for their customers when they request them and limiting the amount of inventory on hand as inventory is spent cash, and cash is KING for survival.

To accommodate such an approach., Business Software, like SimpleManufacturing™, must be able to add Delivery Quantity and Dates, per line item, into existing orders. In addition, such additions must drive the actions necessary to fulfill the demand. Most Business Software generally determines this through its sophisticated Material Requirements Planning function.

Work Order or Job Number Capabilities

Businesses that create a “Job Number” or “Work Order” for every Customer Purchase Order received are frequently called Job Shops. All material planning, ordering, manufacturing, and fulfillment processes are centric on this single order.

Identifying a Job Number and Work Orders necessary for order fulfillment must be linked to the Order line items to accommodate this environment. The Work Orders will identify the product that requires manufacturing and the manufacturing order and timing through Work Order Due Dates. This information will facilitate material purchasing, scheduling, and production planning to ensure successful order fulfillment.

Job Shop Caveats

Job Shops run into the same dilemmas time after time. Here is a list of drawbacks to the Job Shop approach within a manufacturing business.

a) Inflated Inventory

It is common for manufacturers to build more of the product than needed to fulfill the order because of the fear of scrap, attrition, etc. Scrap and attrition, although not expected nor ever acceptable, do happen. Not being able to supply the Customer with the quantity and delivery dates they requested is detrimental to the business. With this safety measure in place, the business ends up with excess material and products. For repeat orders or a request for more products, the business should review all available material and products already in inventory and consider that when creating a new Job Number and set of Work Orders to satisfy this new order demand. Sadly, most don’t either because of the difficulty in obtaining such information on past builds or a denial that such excess material and products exist. The result is a growing inventory.

b) Economies of Scale

Purchasing material based on Material Requirements across all orders, work orders, and existing inventory combines a demand for like material to purchase larger quantities. The larger quantities typically result in reduced Unit Costs, ultimately paying less for the material. The trouble is that Job Shops environments have no idea how much cost saving they would encounter using this method.

Features to Consider with the Order View of any Business Software

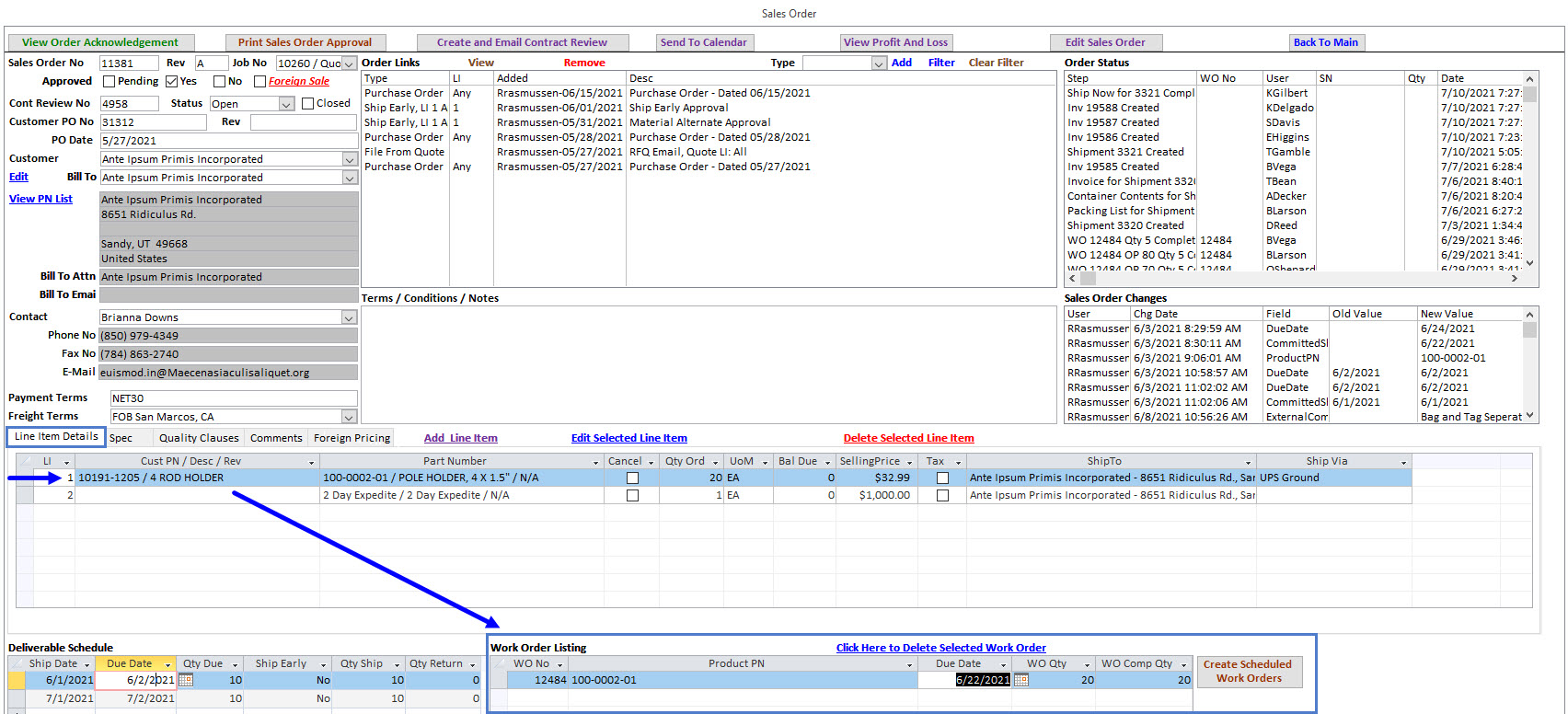

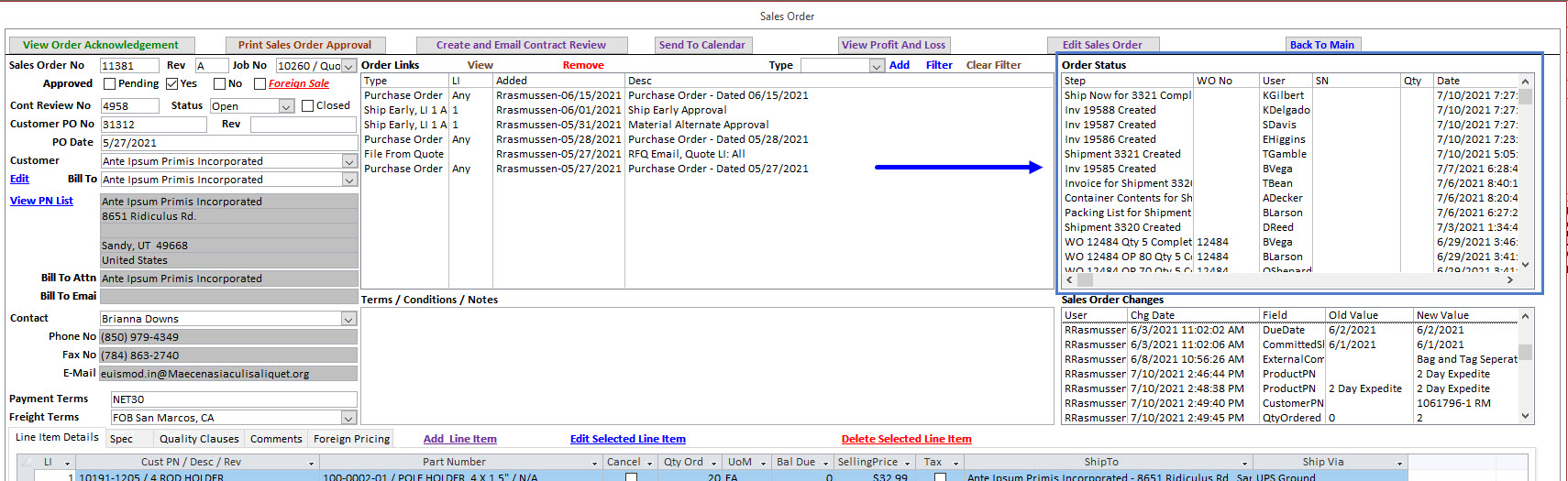

Order Status

As the order progresses through the manufacturing process, it is convenient and efficient to view an order and see where it is within the order fulfillment process. Depending on how the processes and events are set up and what triggers are created will determine how much activity will be seen. For most business software, like SimpleManufacturing™, the order status events are triggered behind the scenes and are not something a user needs to manage or add.

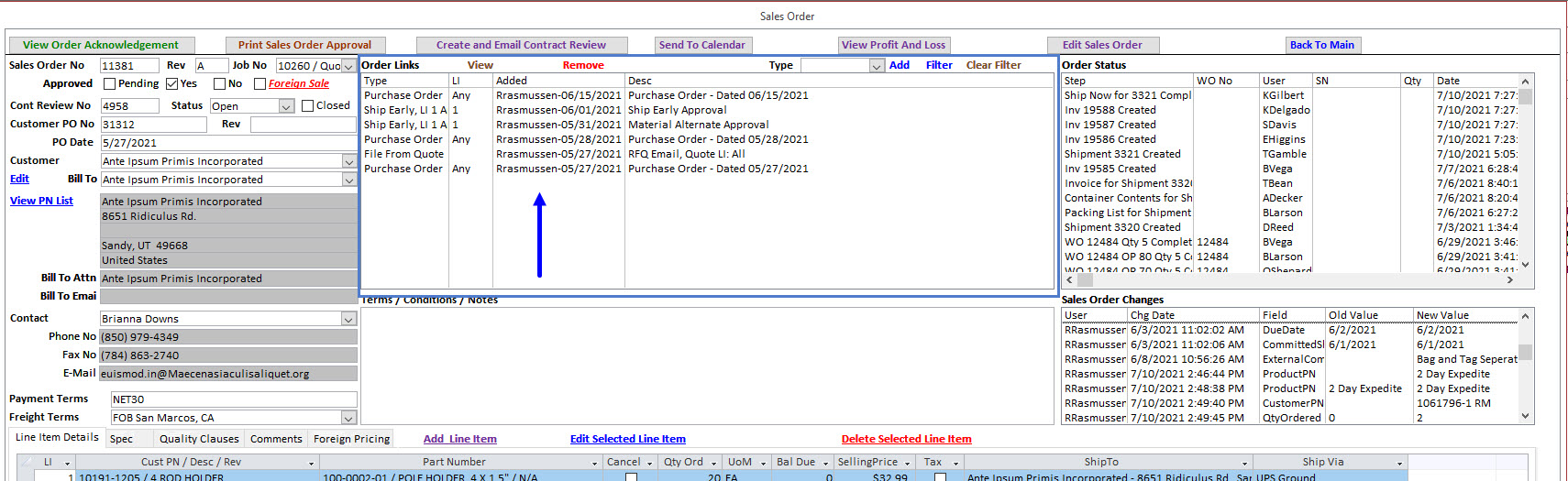

Document and File Linking

Do Customers still send you Purchase Orders via email? Do they include attachments such as a PDF version of the Purchase Order, Drawings, Terms and Conditions, Quality Clauses, Specifications, Bill of Material, etc.? Where do all of these attachments go? How about linking it directly into the Order? Linking Files directly to the order, giving the users the ability to describe the file linked, and providing a single-click option to view the file, saves a lot of time. How often have you searched network folders, asked around, and performed other wasteful exercises to find files regarding an order? The only person who knows where the files are is who added them to a network folder. Not exactly an ideal process. Demand a simple and quick feature to link any document or file to order. Files include emails, drawings, Purchase orders, material lists, etc. Also, demand behind-the-scenes capture of who added it and when it was added.

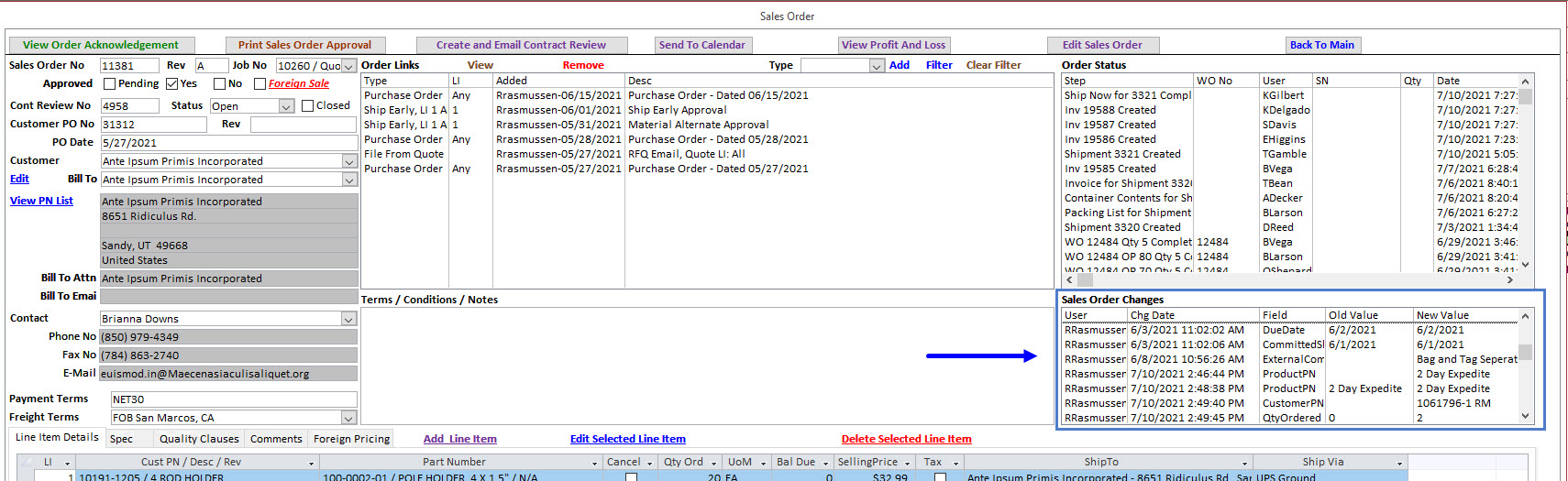

Order Change Log

Changes to existing Orders can have a drastic impact on a manufacturing business. Product Revision Level changes, Quantity changes, Delivery Date changes, Selling Price changes, and the like. Complex businesses have processes to review the changes and decide what actions are necessary due to such changes. A behind-the-scenes capture of the information that changed, such as “was” and “is,” what information changed, who completed the change, and when the change was made, confirms the changes being considered.

Choosing SimpleManufacturing™ as your next ERP / MRP Business Software Solution

A solution like SimpleManufacturing™ will help you scale your operations quickly while gaining real-time insights that help manage every aspect of your order lifecycles. Our flexible approach, with a focus on the efficiency of the order fulfillment process and the seamless integration with your current processes, promotes the building and retention of your customer base. Our flexible approach to order content within the Order Management system allows for the most simplistic case identifying:

- Customer

- What is ordered

- How many were ordered and

- When needed,

But also accommodates the most difficult manufacturing environments, such as Make-To-Order, or supporting the aerospace industry, that may have complex demands such as:

- Customer and Internal Part Number Identification

- Scheduled Delivery Dates

- Scheduled Work Orders

- Multiple Ship to Address(s)

- Specification Requirements

- Quality Clauses

- USA and Foreign Pricing Options

- Serialization

Our focus on efficiencies within the Order Management system resulted in Single-Click features such as:

- Viewing Line Item Part Information

- Viewing Customer Info

- Viewing Order Acknowledgement

- Creating Contract Review for Functional Group Approval

- Sending Out Contract Review requests, and

- Emailing Customer Order Acknowledgment with Digital Signature

In addition, the seamless integration throughout the ERP system provides real-time order status as the order progresses through the fulfillment process.