Supplier Management Software for Manufacturing Businesses

SimpleManufacturing™ Supplier Management Software provides complete Supplier Relationship Management (SRM) capabilities for manufacturers. From vendor selection and supplier performance management to supplier risk management software features, it simplifies every step of your supply chain and helps lower costs.

Key Benefits of Our Supplier Management System

- Supplier Relationship Management (SRM):

Build long-term vendor partnerships for quality and cost savings. - Supplier Performance Management:

Track delivery, quality, and compliance KPIs with detailed scorecards. - Supplier Risk Management:

Identify and mitigate financial, geographic, or delivery risks in real time. - Vendor Management for Manufacturers:

Centralize vendor data, contracts, and payment terms for easy access. - Procurement & Contract Management:

Automate approvals, terms, and compliance audits. - Cost Control:

Reduce total cost of ownership with better negotiation and analytics.

Feature Highlights

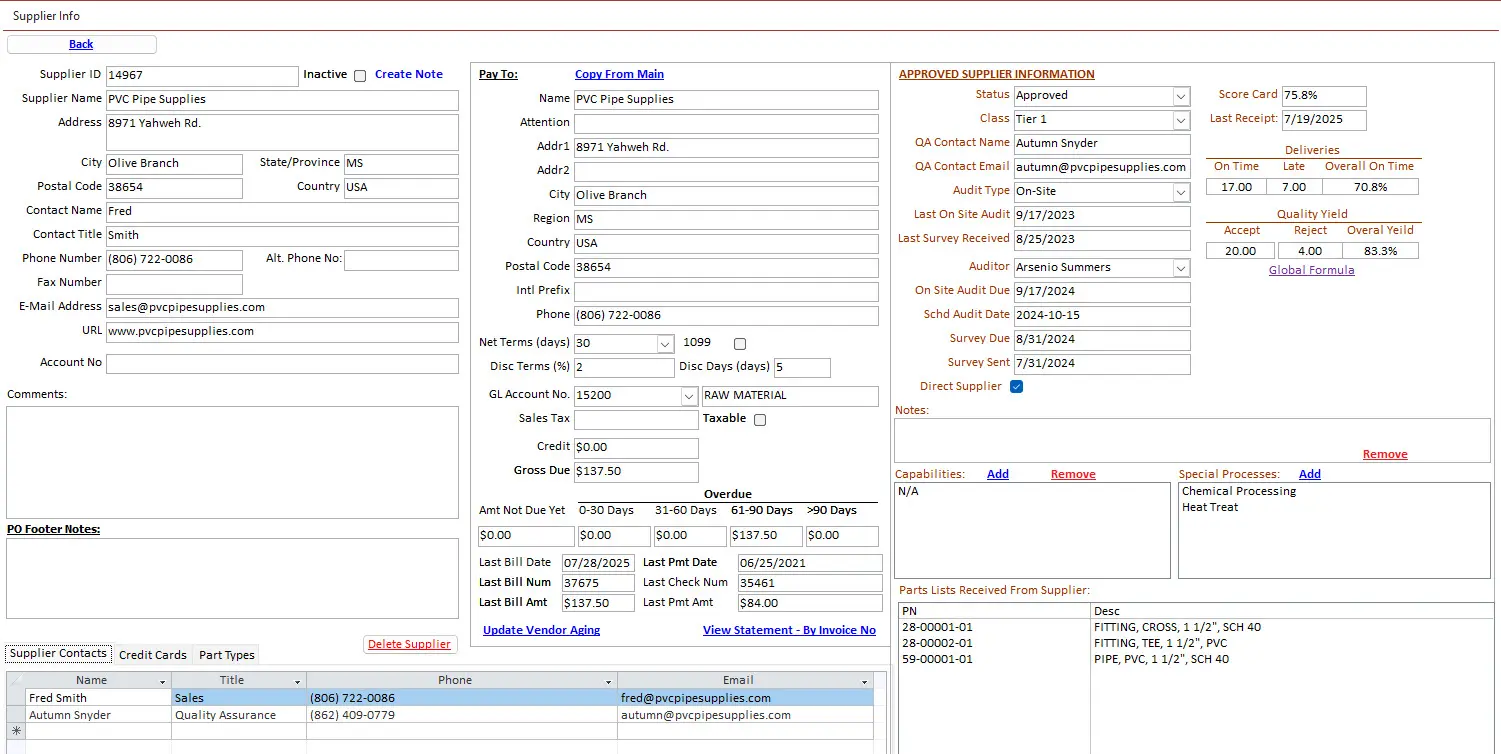

- Comprehensive supplier profiles:

Contacts, Terms, Classification, and Audit Data - Integrated AP information with real-time accounting status

- Supplier scorecard dashboards and automated performance reports

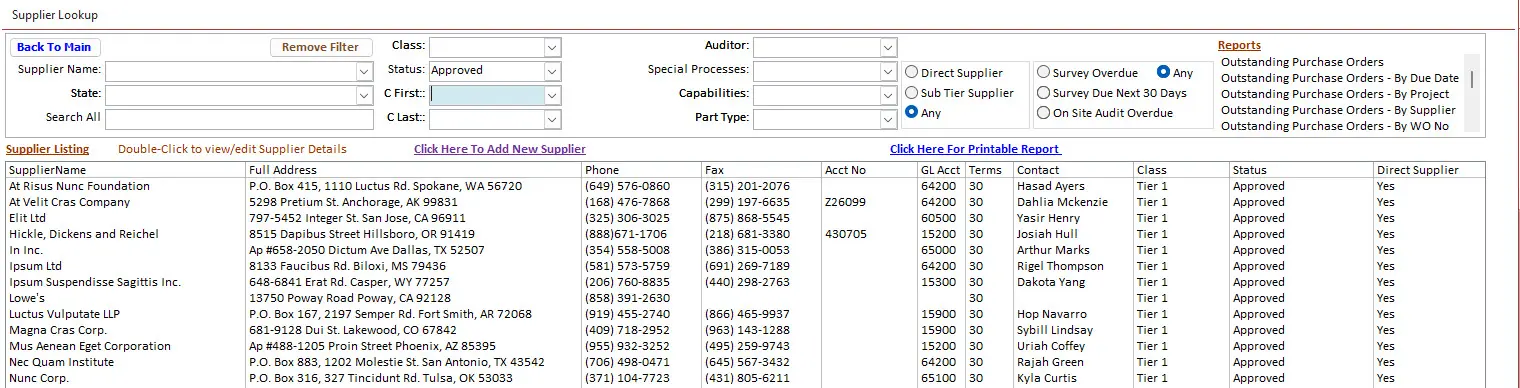

- Fast supplier search & filtering by geography, reliability, or classification

- Unlimited supplier contact records with secure document attachments

Watch This Video to See an Overview of SimpleManufacturing™ Manufacturing Software Supplier Management Module.

Streamline Your Vendor Management Today.

1-858-335-6421