Purchase Order Management for Manufacturers

SimpleManufacturing™ offers an integrated Purchase Order Management system built specifically for manufacturers. Our software helps you streamline procurement workflows, control costs, and ensure materials arrive on time—so your production never slows down.

Why Purchase Orders Matter in Manufacturing

Managing purchase orders is essential to a smooth manufacturing operation. SimpleManufacturing™ ensures:

- Inventory Control:

Plan and track materials to prevent production delays. - Supplier Management:

Monitor supplier performance and maintain vendor consistency. - Cost Management:

Lock in pricing and avoid billing discrepancies. - Risk Reduction:

Ensure clarity with legal purchase documentation. - Workflow Automation:

Automate POs to save time and eliminate manual errors.

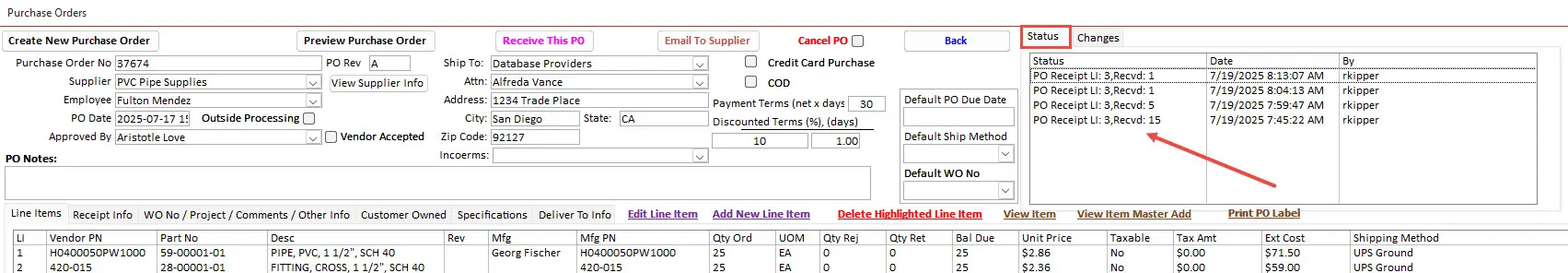

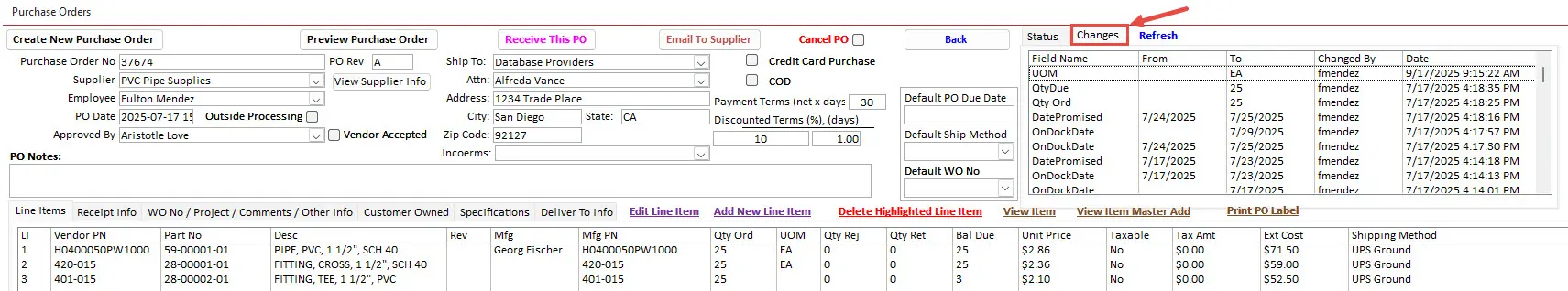

Core Features of SimpleManufacturing™ PO Management

- Automatic PO generation from low inventory triggers

- Supplier contact info and purchase history access

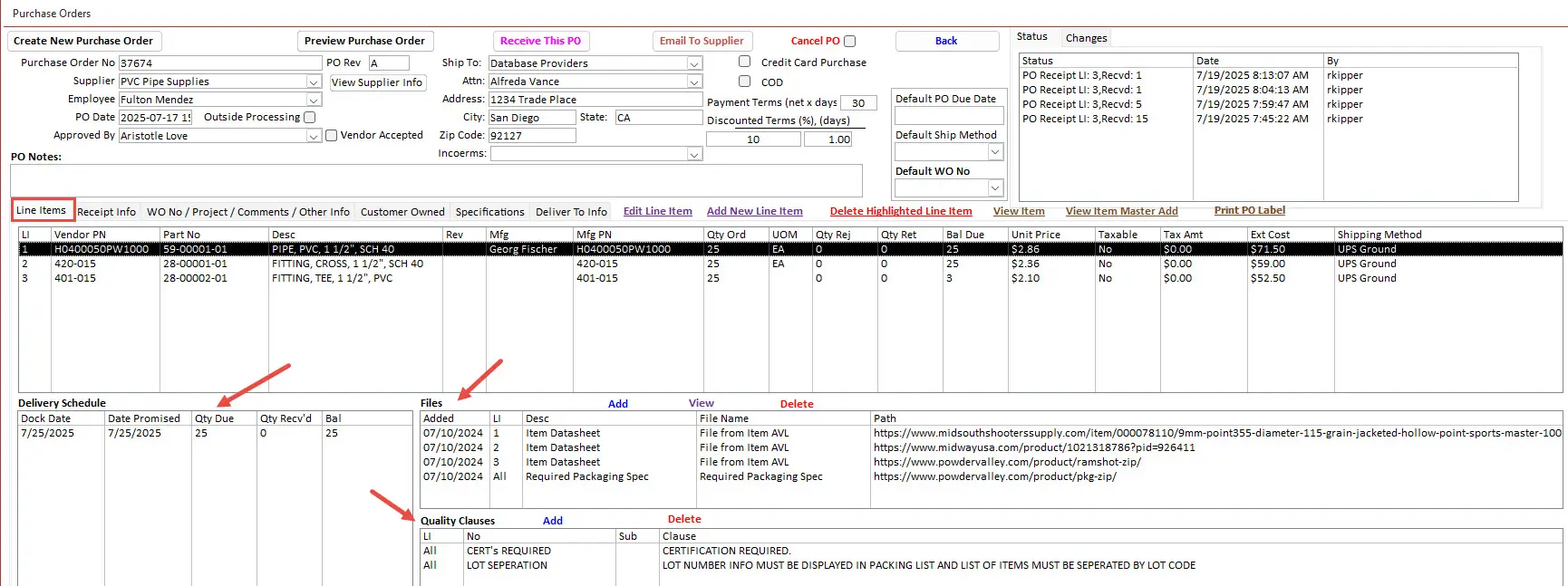

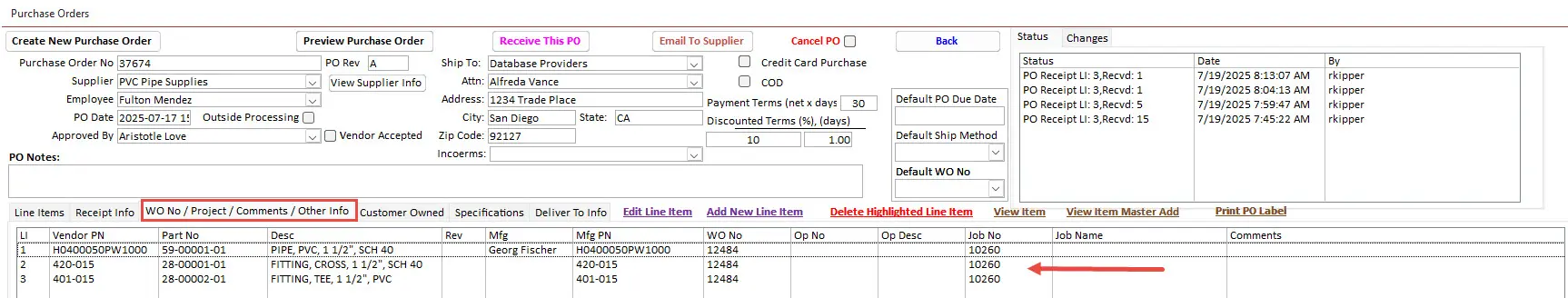

- Line-item controls for quantity, cost, due date, and more

- Multi-level approval workflows

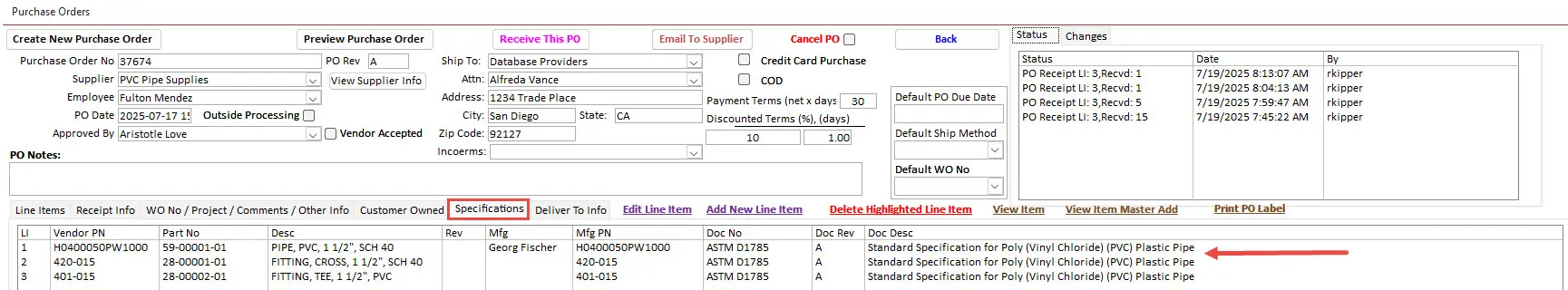

- Linked documents, drawings, and spec sheets

- Email-ready POs with signature and PDF export

- Audit trail and change log for each PO

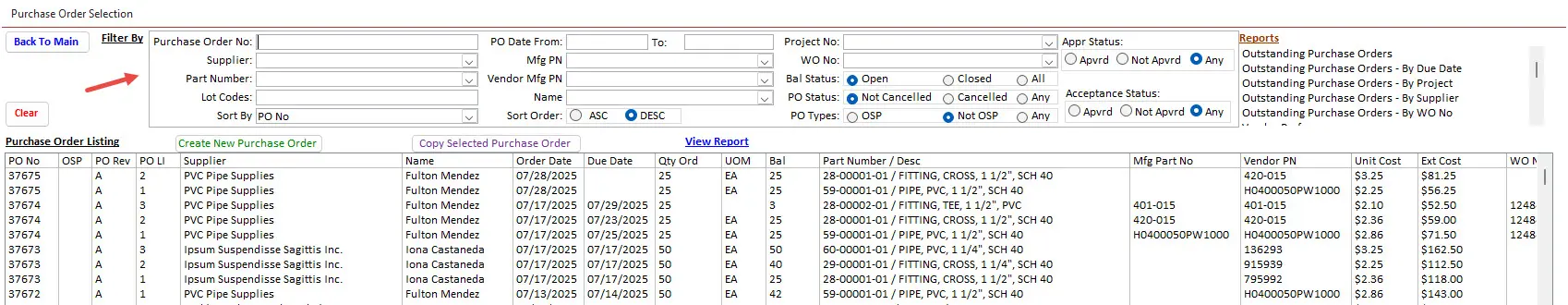

- Search and filter tools by part, supplier, or date

Experience how SimpleManufacturing™ transforms manufacturing.

Explore Full FeaturesTrusted by Manufacturers Who Rely on Precision

From aerospace to electronics, our users depend on SimpleManufacturing™ for reliable, real-time purchase order control. Whether you're managing hundreds of suppliers or just a few key vendors, our platform scales to your needs.

Ready to optimize your procurement?

Get a Personalized Demo