Control Plans In-Use – Inspection Results

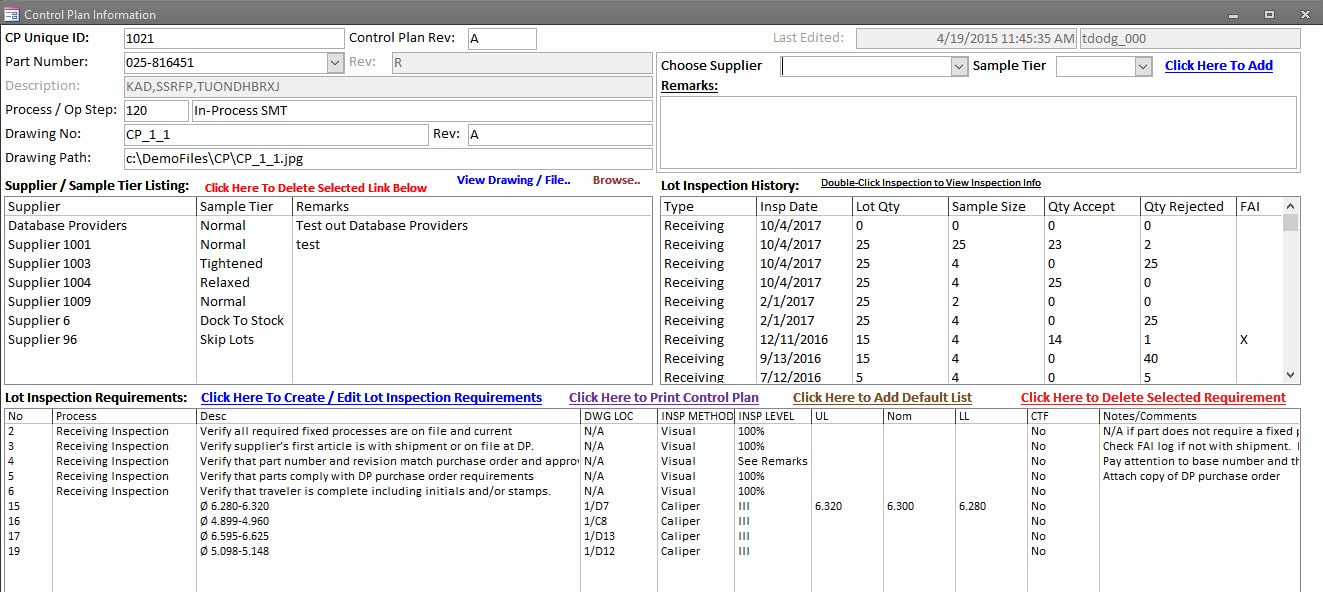

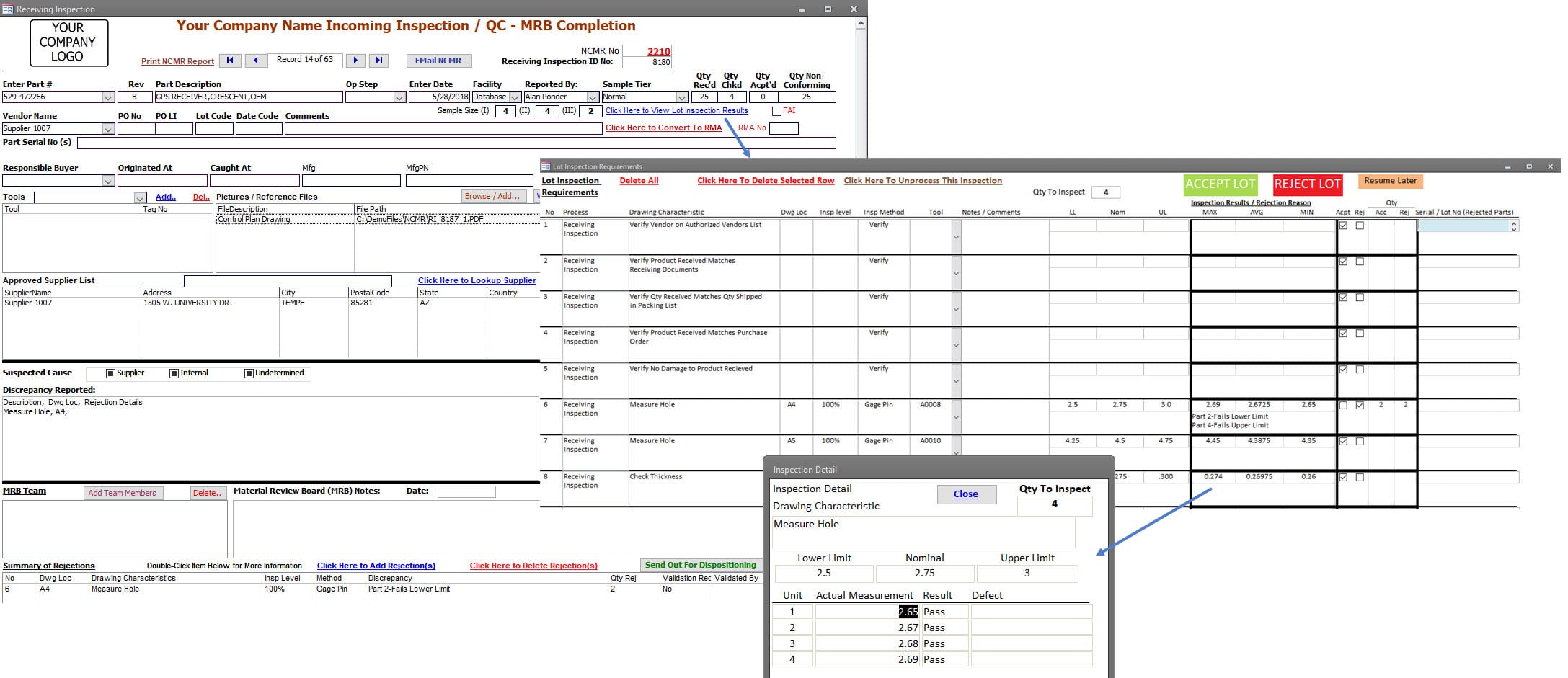

If a Control Plan exists for a Receiving Inspection process, the Control Plan Definition is copied into the Receiving Inspection record. The Receiver / Inspector is notified of the Inspection Method by combining the Part Number, Revision Level, and Supplier defined in the Control Plan. If the Inspection Method is an AQL Sampling Plan, the Number of Pieces to be inspected is provided based on the Lot Size of the Quantity Received.

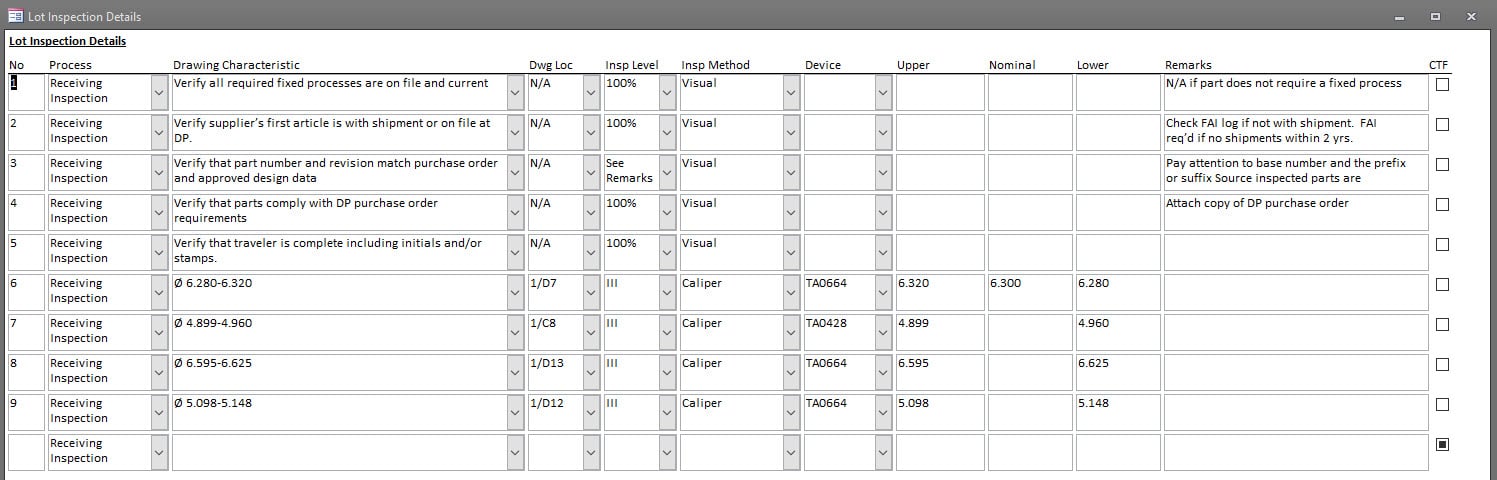

The Inspector must complete all sections of the Inspection Report. When a Measurement is required, the Inspector is provided an entry screen to enter each measurement of each unit inspected.

Based on the Inspection results, the Inspector will either Accept or Reject the Lot. If the Lot is rejected, a nonconforming record is automatically created, and the defects are itemized in the inspection record for review and disposition.

Process Inspection points follow the same process.