Nonconforming / Rejected / Failed Material Processing

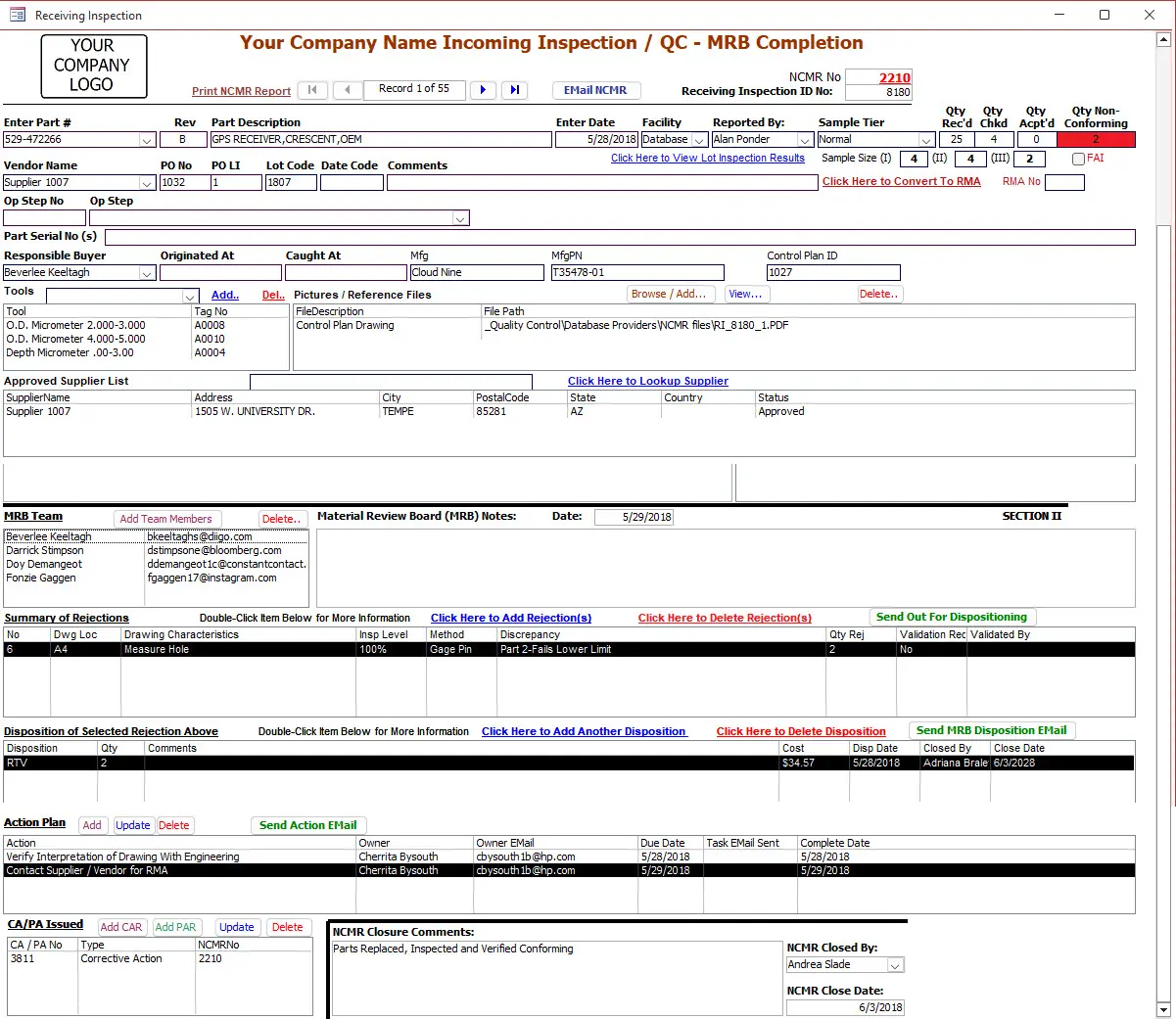

Identify, track, and manage nonconforming (NC), defective, rejected, or failed materials before they go further in production. This module ensures that defective product is segregated, disposed of properly, and documented for quality traceability and control.

Key Principles of Nonconformance

The nonconformance (NC) process should be a closed loop

- Identify nonconforming parts

- Segregate them physically

- Disposition them (rework, scrap, return, use-as-is)

- Verify the actions

- Close the record.

Module Features

Identify Nonconformance

Log parts and materials that fail inspection or deviate from specifications.

- Record part number, revision, quantity, discrepancy details

- Tag, label, package, and physically segregate nonconforming items

- Link nonconformance to orders, batches, or suppliers

Disposition Actions

Manage what happens to nonconforming items via supported disposition options.

- Rework, scrap, use-as-is, return-to-vendor

- Support multiple disposition actions per lot if needed

- Electronic approval and review workflows

Link Documents & Files

Attach supporting documentation and evidence to nonconformance records.

- Drawings, emails, defect images, test results

- Supplier requirement documentation and inspection reports

Tool & Calibration Tracking

Manage calibrated measuring devices used in inspections and nonconformance.

- Track instrument usage and expiration

- Alerts when calibration is expired or due

Disposition Review / Closure

Review and close nonconformance records once actions are completed and verified.

- Single-click email to disposition parties

- Require supervisor or password-protected approval

- Generate closure actions and confirm execution

Defect Reporting & Metrics

Generate reports and metrics to monitor quality, trends, and cost of nonconformance.

- Open nonconformances, KPIs, top defects

- Cost of poor quality, supplier scorecards, trend charts

- Inspection reports by device, date range, defect type

Corrective Action Integration

Trigger corrective action workflows from nonconformance records.

- One-click initiation of CAPA / 8D process

- Pre-fill relevant nonconformance data into the CAPA record

Advanced Search & Filtering

Quickly find nonconformance records using robust filters and search tools.

- Search by customer, supplier, part number, date range

- Filter by defect type, work center, disposition type

Watch Our Nonconforming Material Processing Demo

See how SimpleManufacturing™ Nonconforming Material module simplifies the handling of defective and non-conforming material— from detection and tagging to disposition, reporting, and corrective action.

This video walks you through key features including real-time NC tracking, automated reports, and integration with corrective action workflows, ensuring full ISO 9001 and AS9100 compliance.

Call for a Free Demo:

858-335-6421