Best Practices for Employee Training in Manufacturing

Developing and Growing Employees Thru Training

Equipping Employees with the necessary skills and knowledge to enhance their performance and contribute to the company’s success.

What is Employee Training and Requirements Management in Manufacturing and Service Industries?

The manufacturing and service industries are complex work environments that require employees to possess skills and competency levels to perform the tasks for which they are responsible. Identifying and managing each employee can be daunting. A well-managed employee training program offers many benefits. First, consistent training builds a more robust workforce. Secondly, workforce skill gaps can be identified and closed. Lastly, the training records of a force can prove that any regulatory, environmental, and safety standard requirements are met.

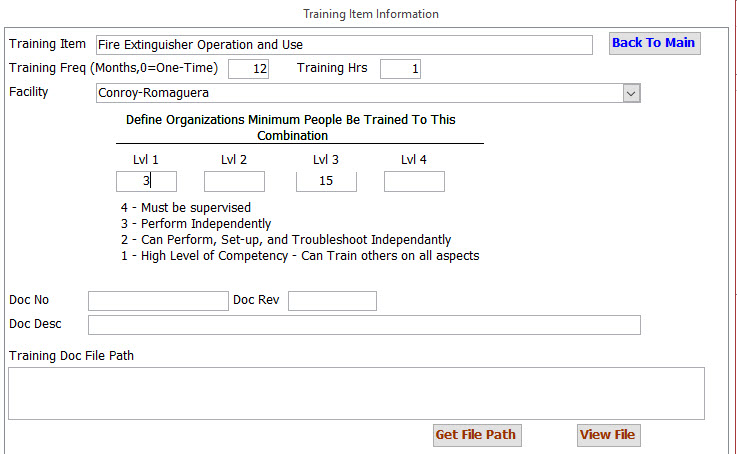

Definition of a Training Item

A Training Item is a unique item that identifies a specific training. In the complex manufacturing and service industries, there are many types. First, the item can be a policy, procedure, work instruction, form, or any combination of those within the organization’s ISO900x or AS9100 program. Secondly, they can be an OSHA requirement such as Fire Extinguisher, CPR, Blood-Bourne Pathogens, Fork-Lift, Vision, Reading and Writing Skills, and Equipment Operation training. Thirdly, they can be trained on customer requirements or industry specifications. Lastly, onboarding training is provided to all new hires.

Frequency of Training

As stated, it is a default duration of how often the organization believes the workforce will be re-trained for any specific Training Item. Government regulations may dictate the frequency of specific OSHA and other types of training. However, most training items can be set to the duration the organization deems appropriate.

Linking of Training Item to Quality Management System Document

Most training within the Manufacturing and Service Industries revolves around training a Policy, Procedure, Work Instruction, and Forms. The training item can link to the Quality Management System document in those cases. Once this link is established, the document can be viewed quickly should it need to be referred to in any capacity.

Minimum Work Force Training

For each training item, the organization will identify the minimum workforce to be trained. This is used to identify training or skill gaps within the workforce. For example, in the manufacturing and service industries, the organization might want to have a minimum of 3 employees trained to operate the forklift, a minimum of 2 employees trained to set and use a specific piece of equipment, or a minimum of 4 employees trained to a particular mission-critical process. When these minimums are established, the training gap analysis report will indicate where the deficiencies are.

Flexible Approach to Identifying Work Force Requirements

SimpleManufacturing™ uses a unique approach to establishing workforce training requirements. The Training Matrix module allows the organization to develop training requirements using five options. The first matrix option available is to identify the training items required when performing a specific process. The second matrix option available is to identify the training items when assigned to a particular work center or department. The third matrix option is to identify the required training items based on the specific job title. The fourth matrix option available is to identify the training items of particular employees. The last matrix option available is to identify the training items necessary to work on a specific product line or series of product lines.

Process Training Requirements

The manufacturing and service industries have many processes. Many organizations have focused their internal auditing program around processes. The organization creates and manages the list of Processes. Those Processes might include Order Entry, Contract Review, Bill of Materials Management, Change Control, etc. The process can vary in broadness and identified at the organization’s discretion. A list of the training items required to complete each process successfully can be specified. Furthermore, the frequency of re-training can be set differently from the default established for the specific training item. An example of where this may be beneficial is Fire Extinguisher training. A process that occurs in an area of the manufacturing floor that may have nearby flammable items may require that the workforce working in that area be re-trained on the use of a Fire Extinguisher more frequently than an employee that resides in an office far away from the site, where the probability of a fire is drastically reduced. The Default duration for the Fire Extinguisher training item may be once every 24 months. Still, the workforce working with nearby flammable items might want the re-training to occur every six months.

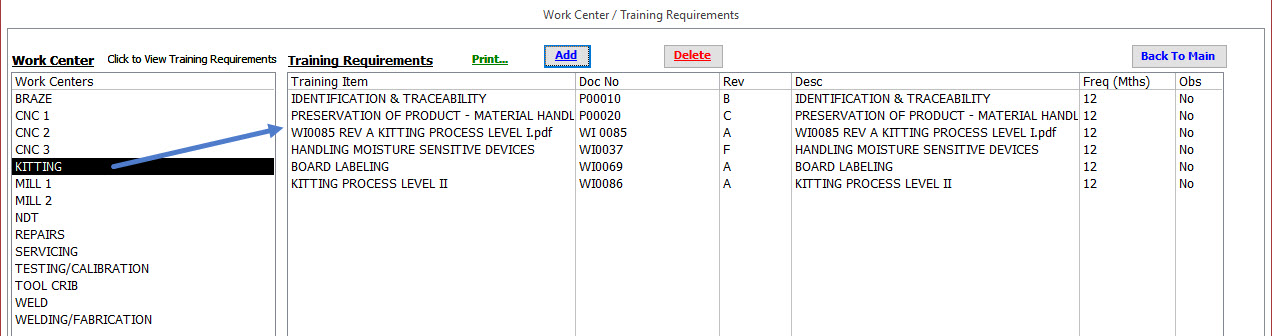

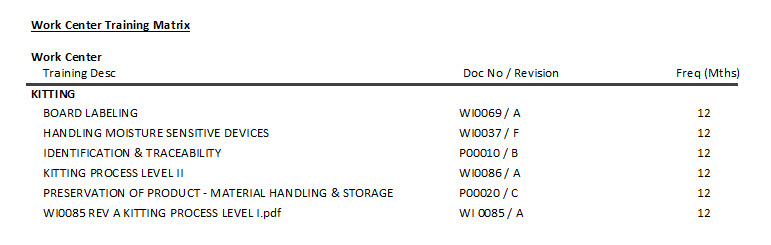

Work Center Training Requirements

The manufacturing and service industries typically have many work centers, departments, work cells, etc. These might include kitting, CMM, NDT, X-ray, SMT, cleaning, marking, etc. The organization creates and manages the list of Work Centers, Departments, or Work Cells. A list of the training items required to work in such area can be identified for each Work Center, Department, or Work Cell. Furthermore, the frequency of re-training can be set differently from the default established for the specific training item.

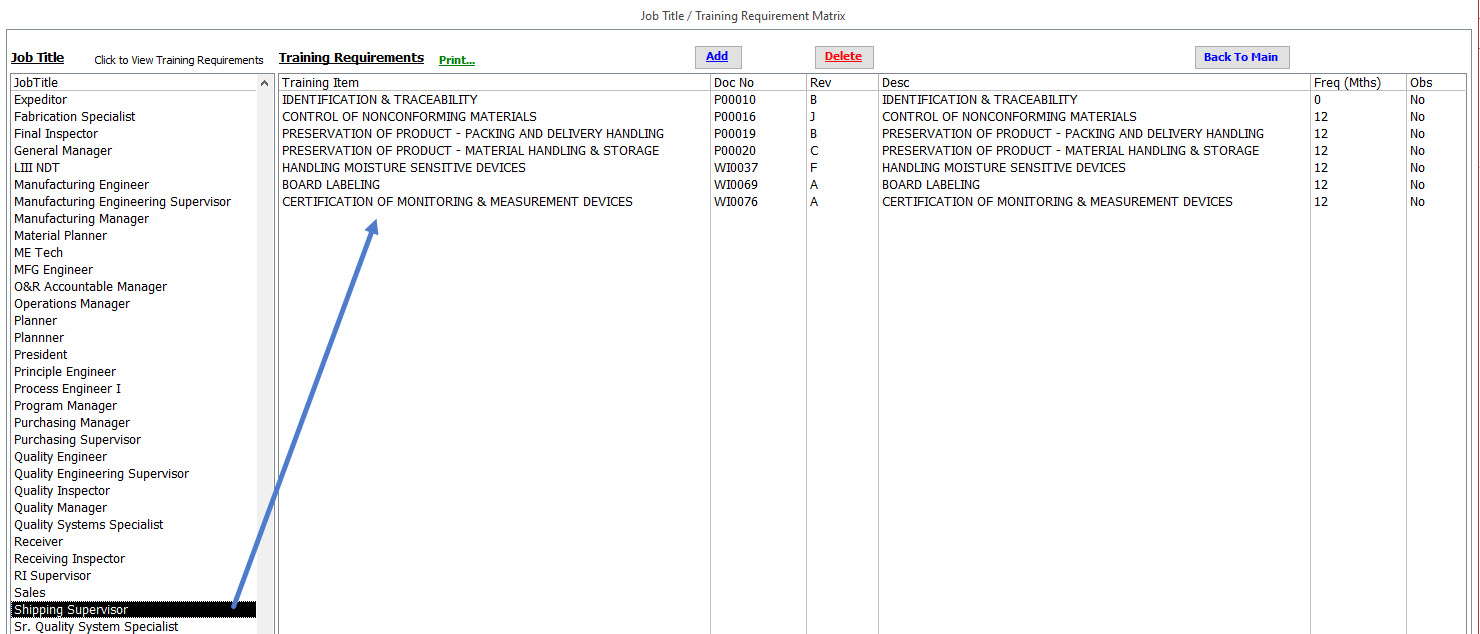

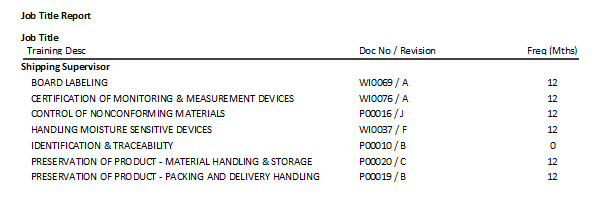

Job Title Training Requirements

The manufacturing and service industries may establish Job Titles for the workforce. Job titles and descriptions can vary from organization to organization. The organization creates and manages the list of job titles. A list of the training items required for a specific Job Title can be identified. Furthermore, the frequency of re-training can be set differently from the default established for the particular training item.

Employee Training Requirements

Supervisors can select specific employees and identify the training items required of them. Furthermore, the frequency of each training item added can be set differently from the default established for the specific training item.

Product Line Training Requirements

In some manufacturing and service industries, the workforce is dedicated to a product line or series of products. The organization creates and manages the list of Product Lines or Products. A list of the training items required to work on a specific Product Line or series of Products can be identified. Furthermore, the frequency of re-training can be set differently from the default established for the particular training item.

Most Popular Use of the Training Matrix

Although the Training Matrix offers a flexible approach to establishing the workforce training requirements, the two most popular options are a combination of Work Centers and Job Titles. Work Centers typically have leads or supervisors who are subject matter experts on the various tasks carried out within them as well as the overall quality management system. Those leads can quickly identify the appropriate training items for each Work Center. In addition, leaders, managers, and supervisors typically understand the job descriptions of each job title. Again, those leads, managers, and supervisors can identify the training items each Job Title requires.

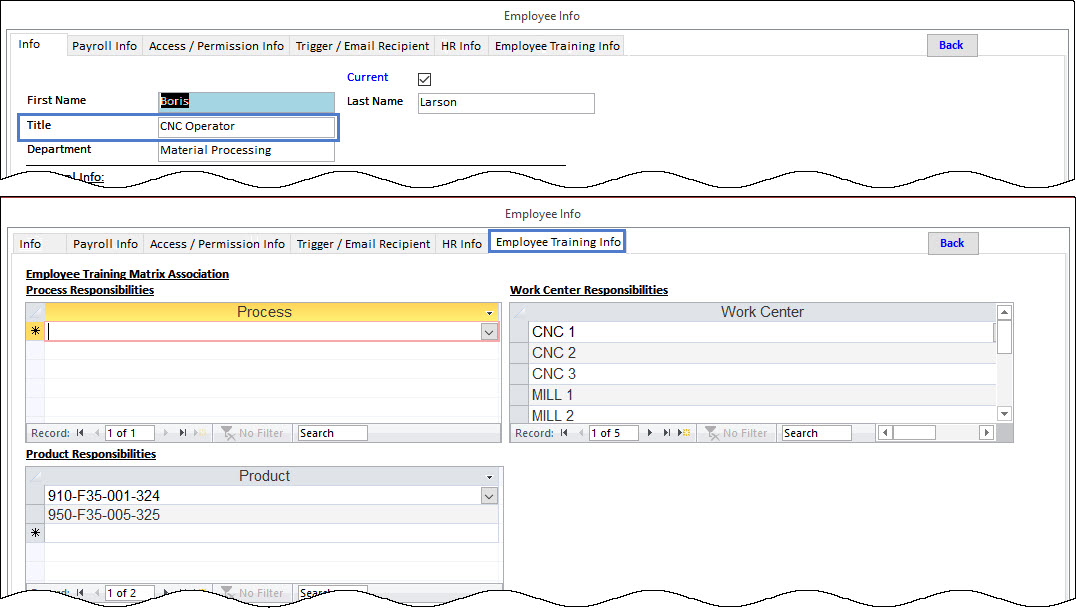

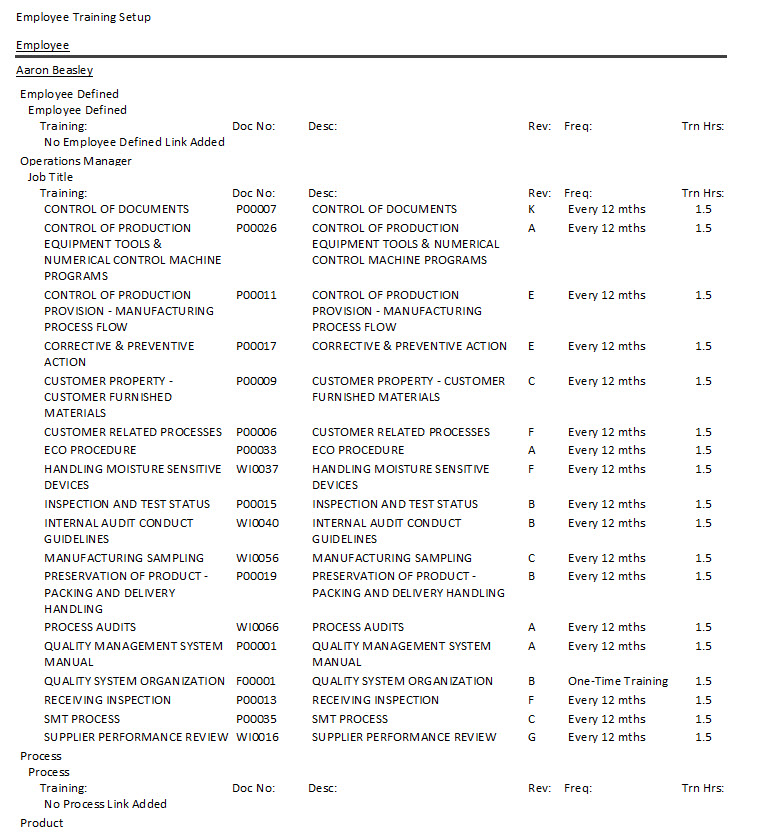

How SimpleManufacturing™ Links Workforce to Requirements

Within the Employee module of SimpleManufacturing™, the Job Title of each Employee can be identified. When doing so, the Employee will inherit all the training requirements specified within the Job Title matrix. In addition to job titles, employees can be linked to unlimited product lines, work centers, departments or work cells, and processes. When connected, the Employee inherits all the training requirements identified within any of those Matrix options. This training requirements list is real-time and can be viewed anytime. The functionality within SimpleManufacturing™ automatically generates the training requirements from all matrix options and employee links.

Definition of a Training Record

Upon completion of training, a training record is entered. The process of entering the training record must include a few essential attributes. The essentials consist of:

The Who, When, and What of Training

Always record who was trained, the date of training, and the training item. When the Training Matrix within SimpleManufacturing™ is used to establish the training requirements of the workforce, the frequency will be used to set the expiration date of the training automatically. When the training matrix is not used, the default frequency of the training item is used to derive the expiration date of the training. In addition, the trainer should be identified. In most audits, some form of objective evidence will need to be presented to recognize that the trainer has the competency and experience level to perform the training.

Training Levels

Training Levels are one way to identify the extent of the training provided and the competency level of those trained. It is the primary source used for the training gap analysis. An example of how this is used is training on operating a piece of equipment. In this case, as many as four levels can be identified.

Level 1

Employees’ training and experience level indicate they must be supervised while operating the equipment.

Level 2

Employee training and experience level indicate they can operate the equipment independently.

Level 3

Employee training and experience level indicate they can operate, set up, and troubleshoot the equipment independently.

Level 4

Employee training and experience level indicate they can train other operators on all aspects of the equipment.

Training Rosters

When a training roster is used, and signatures are added as proof of attendance, these rosters can be linked to the training record entry. Connecting the training roster to the training record allows for quick retrieval should the need to show objective evidence of completed training.

Training Certificates

In addition to training rosters, certificates can be linked to each training record. Whether it be a wallet-sized certificate or one to hang on the wall, linking them to each training record will provide easy access should the certificate need to be printed out. Certificates should be automatically created as a result of each training record entered.

Test Results

In some situations, a post-training test is completed to validate the comprehension of the training. In those cases, the test grade should be recorded. For instance, there is typically classroom instruction, driving instruction, and observation of forklift operation for forklift training. The training software must be able to record both the classroom and driving grades.

Most Effective Approaches to Ensuring Up-To-Date Training

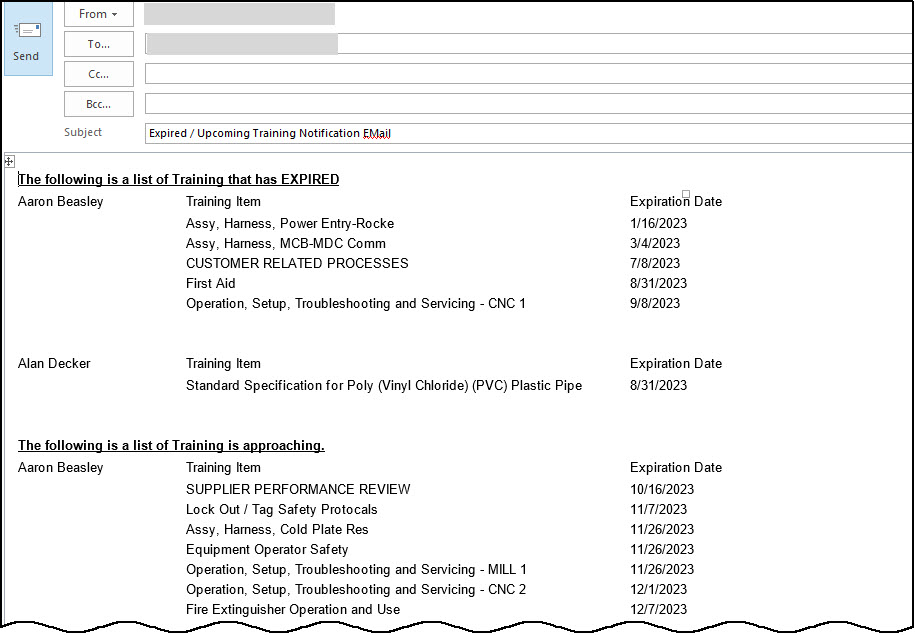

Automatic Notification

Any workforce training tracking software should be automated to send notifications of expired training and upcoming training needs within the next 30 and 60 days. Pushing information out to the appropriate parties has proven the most effective. In addition, this information must be delivered to the correct individuals. At a minimum, the employee, manager, and human resources must be notified. The arrangement for training can take time, so it is in the organization’s best interest to be notified well in advance to prevent workforce training from expiring. Typical automation approaches are through emails, text messages, and mailings.

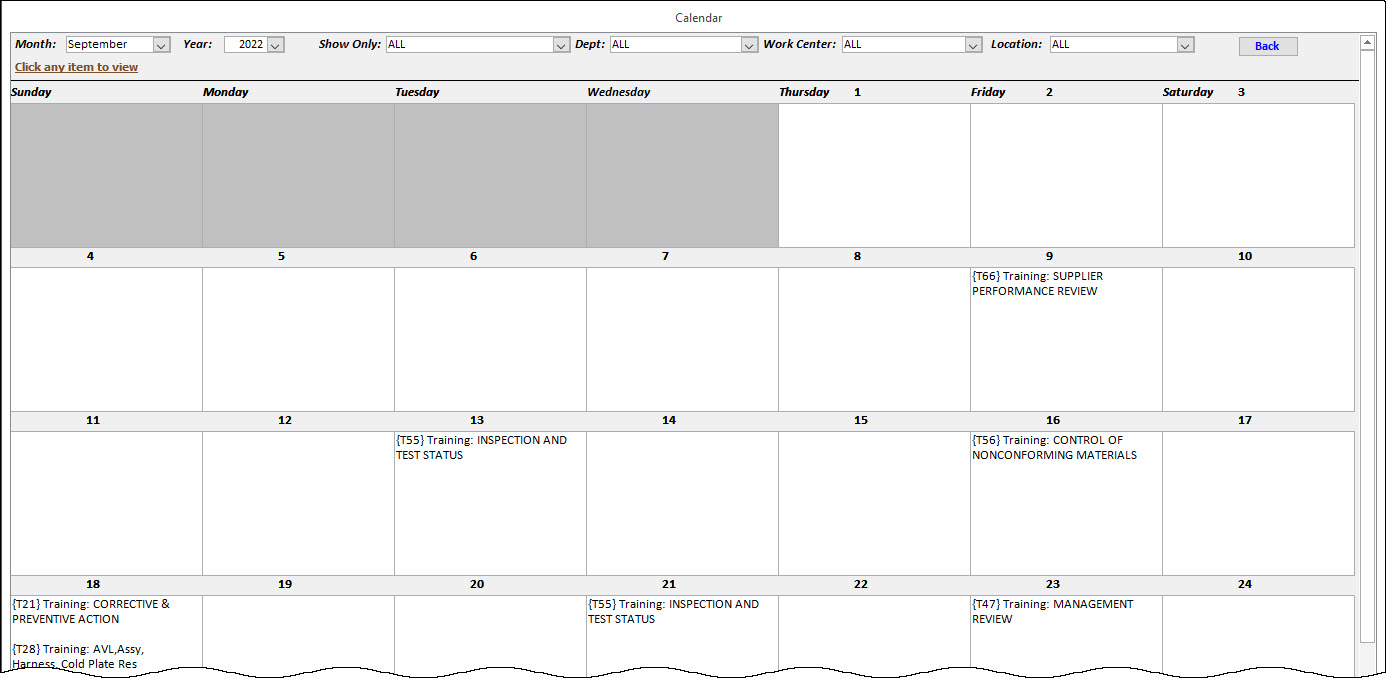

Training Calendar

A real-time training calendar, automatically updated every time a new training requirement is added or removed and new training records added, is a powerful option for viewing the upcoming training needs. The training calendar should also allow managers to view their workforce’s training needs and whatever choices they want to view, whether by work center, department, work cell, process, product, job title, or any combination in between. This extra tool allows managers to plan. Ensuring none of their workforces ever reach an expired training situation.

On-Demand Reports

Reports play a crucial role in viewing training requirements and the status of those requirements.

Individual Training Requirements and Status

Need reports to view employee’s training requirements and status. These reports must have a flexible filtering approach. Managers and Human Resources must be able to view particular individuals and a list of those within a work center, department, work cell, process, product line, or job Title—a simple approach becomes a valuable tool.

Training Requirements and Status of Each Training Item

Need reports to view training items and list the employees required to be trained and their training status.

Current Training Matrix Requirements

Need reports to view Training Matrix options and the current training requirements within each Matrix. When using the Training Matrix tool to establish the training requirements, these must be reviewed regularly to validate the necessity.

Training Gap Analysis

A training gap analysis is a must-have report that indicates the expected number of trained workforce versus the actual number of skilled workforce for any training item. This gap analysis tool helps determine the deficiencies, or “Gaps,” between what is required and what is actually. Reviewing this report and taking the necessary actions to fill the gaps using additional training strengthens the workforce and reduces the risk within the organization.

SimpleManufacturing™ is an intelligent choice for managing Employee Training and Requirements in Manufacturing and Service Industries.

SimpleManufacturing™ includes a practical approach to employee training, tracking and managing training requirements and training status of the workforce. It also includes all of the modules, features, and functions necessary to successfully manage the day-to-day operations of any manufacturing or service company. To see more about what SimpleManufacturing™ can do for your company, visit us at www.simplemanufacturing.com. Our customers’ needs and feedback have always driven SimpleManufacturing™ features and functionality.

Choosing SimpleManufacturing™ as your next ERP / MRP Business Software Solution

The ERP Software you choose now will determine your company’s success. Please pay particular attention to its scalability, current features, and ability to be modified to meet your future business needs. Our flexible approach, focusing on efficiency and seamless integration with your existing processes, with the expectation of change, provides a long-lasting solution.