Inspection Control Plans for Manufacturing

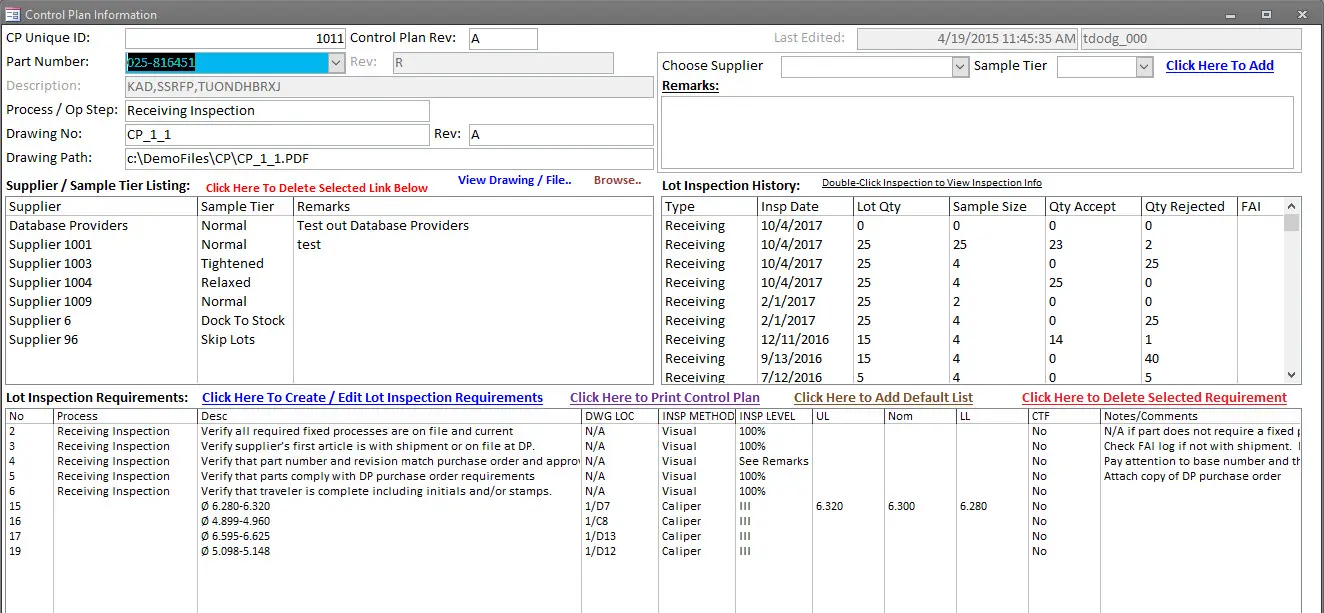

Our Control Plans module enables manufacturers to define and enforce inspection control plans with clear inspection instructions and criteria. By linking inspection points to operations, route steps, and BOMs, you ensure consistent quality checks across production.

Core Features

Define Inspection Points

Specify key checkpoints in the manufacturing process for inspections.

- Associate with operations or routes

- Link to parts, BOMs, or work orders

Inspection Instructions & Criteria

Provide detailed instructions with pass/fail criteria and tooling requirements.

- Text, symbols, or diagrams

- Lower/upper tolerance, sample size, measurement tools

Sampling Plans & Frequency

Define how often inspection is done — 100%, periodic, or statistical sampling.

- Per part, per batch, per time interval

- Adjustable sampling rules

Link to Real-time Inspection

During execution, inspectors follow control plans directly in the system for consistent results.

- Real-time data capture

- Rejects feed into nonconforming module

Historical Inspection Data & Traceability

Maintain records of inspections over time for analytics and audit evidence.

- Inspection outcomes, defects, timestamps

- Trace to lot, part, operation, inspector

Reporting & Analytics

Generate reports on inspection performance, defect trends, and process capability.

- Top defects by operation or part

- Inspection yields, rejection rates, trending charts

Explore Related Quality Assurance Modules:

Nonconforming Material Processing Corrective Action Employee Training Management Internal Auditing Calibration Management Preventive Maintenance Contract Reviews Document ManagementCall for a Demo:

858-335-6421