Account Receivables – Definition and Explanation

Become an Expert in Item or Part Management with Manufacturing Software

Learn:

What is an Account Receivable?

How is it created in SimpleManufacturing™?

Managing AR is easy with SimpleManufacturing™

Dedicated Section within SimpleManufacturing™ Financial Management Module

Easily Search, Find and View

Continue Reading More…..

BOOK A DEMO!

What is an Account Receivable?

The amount of money owed to the company from 3rd Parties for goods or services already rendered, and not yet paid for, is considered Account Receivables (AR). On the Balance Sheet, Account Receivables are listed as a Current Asset because there is an expectation of payment within one year. Furthermore, Accounts receivable, receivables, or unpaid Invoice, represent a line of credit extended by a company and normally have terms that require payments due within a relatively short period. Common periods used are within 30, 60 or 90 Days. Most line of credits have a maximum amount set and is set by evaluating each party’s financial status. For an explanation on Why Managing Account Receivables is important, click here.

How is it created in SimpleManufacturing™?

Most Account Receivables are created through the Invoicing process. An Invoice is a notice of payment for a good or service rendered, the amount owed, and when the amount is to be paid. Invoices are a legal obligation for a 3rd Party to pay the debt. Therefore, due to its legal nature, Account Receivables can be used as collateral to secure loans and are included in the company’s working capital.

Managing AR is easy with SimpleManufacturing™?

The management of Receivables is accomplished through SimpleManufacturing™ invoicing and payment receipt processes. Invoices automatically increase or add to the Account Receivables, and recording the payments of invoices, decreases the Account Receivables.

Using SimpleManufacturing™ Financial Management module

SimpleManufacturing™ offers many options for understanding the current state of Receivables.

Reports

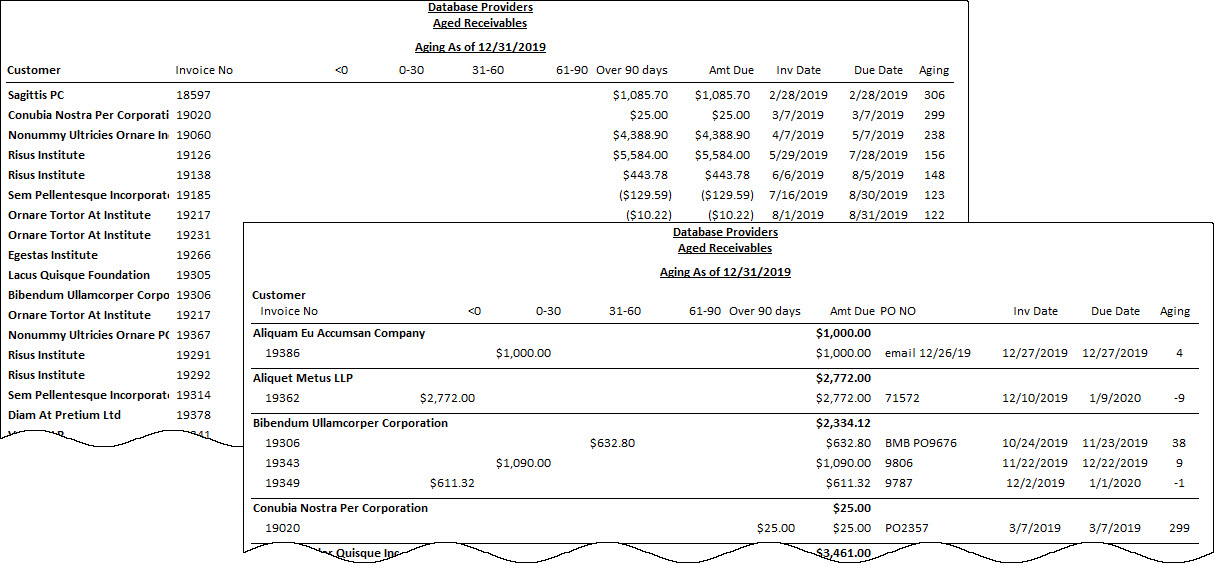

Several reports identify the party, the monies owed, when the funds are due, and the Aging. Below are some examples of those reports.

Dedicated Section within SimpleManufacturing™ Financial Management Module

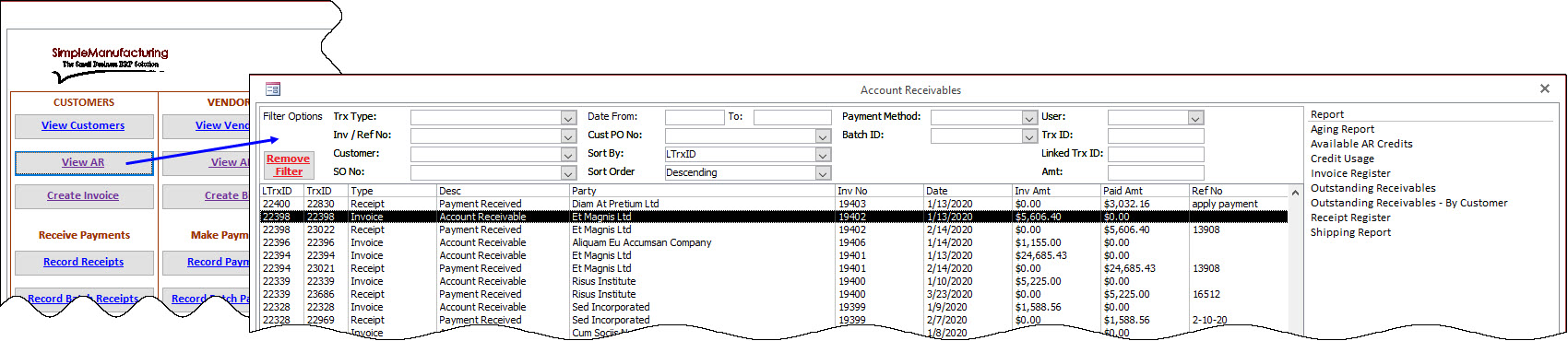

Account Receivables are managed within the SimpleManufacturing™ Financial Management module. Since it is common for companies to have dedicated personnel focusing on AR, SimpleManufacturing™ also has dedicated a specific area to it.

Easily Search, Find and View

Finding Account Receivables, regardless of status, is simple and easy using the SimpleManufacturing™ AR module. Various options exist to find any account receivables. Standard search criteria include:

- Party or Customer

- Invoice Dates or Due Dates,

- Invoice Number or Unique reference,

- Sales Order Number,

- Customer Purchase Order Number,

- Batch Processing ID,

- Payment Type.

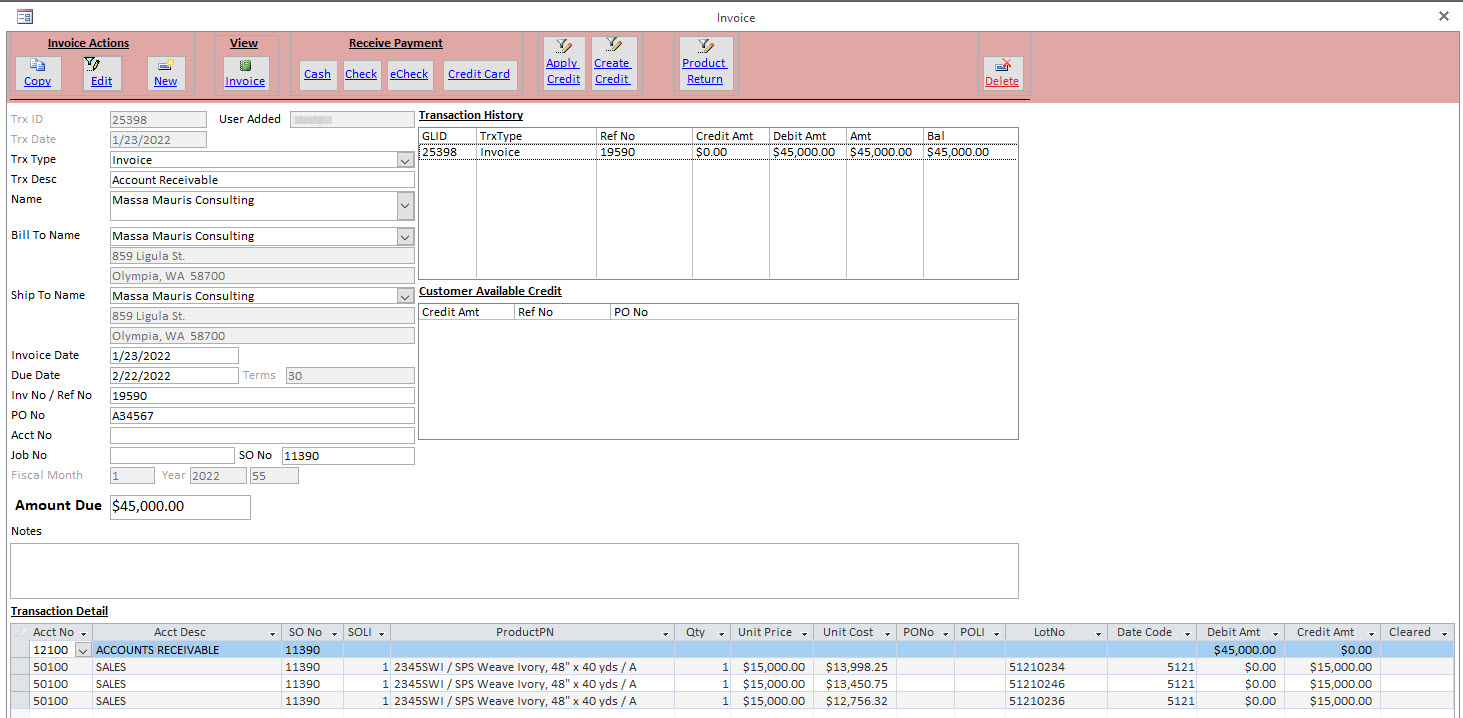

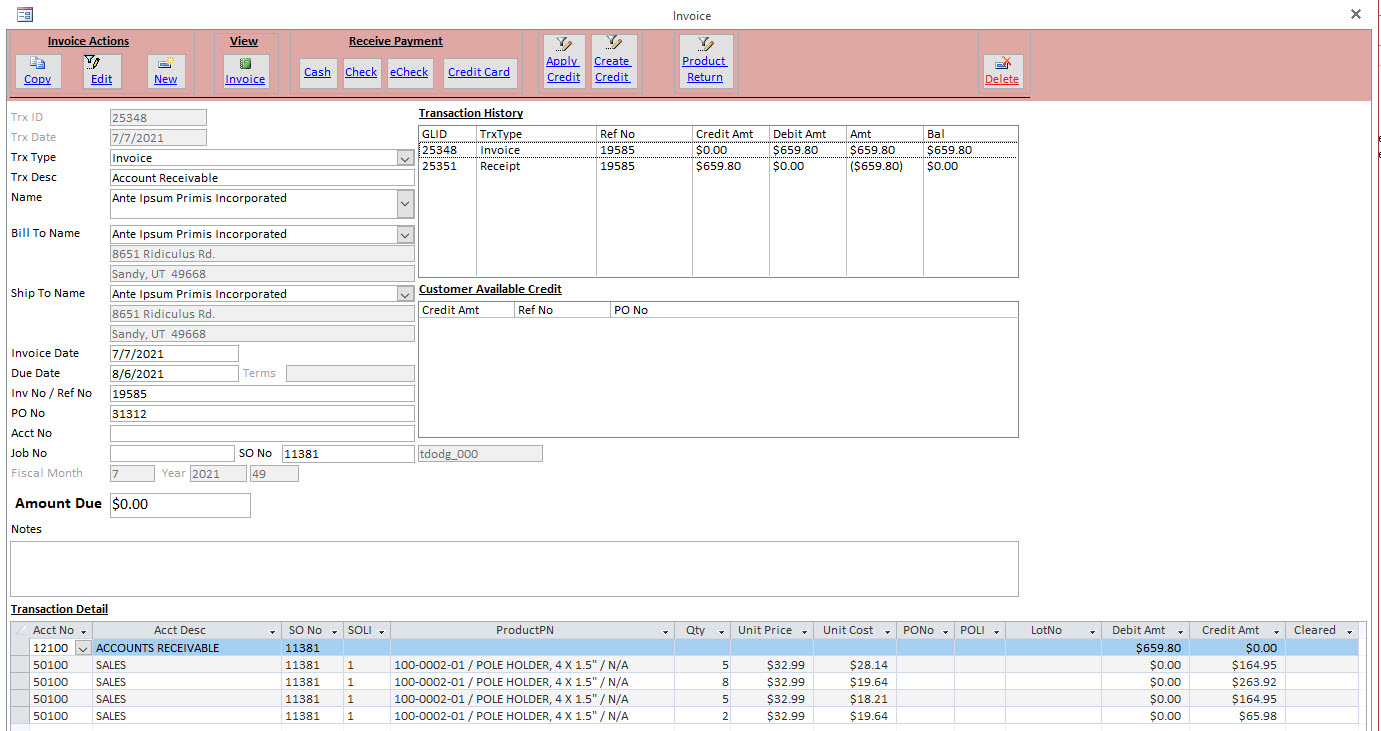

Most Common Account Receivable is an Unpaid Invoice

The most common account receivable is an unpaid invoice. SimpleManufacturing™ invoices contain standard information such as the Party or Customer, a unique Invoice Number, the Amount Owed, and the Payment Due Date. Additionally, many functional attributes are included. Those attributes consist of the following:

- Ship To Party and Location

- Customer Purchase Order Number,

- Work Order Number,

- Sales Order Number,

- Detail information on each item, such as Description, Quantities, Unit price, Unit cost, Lot Numbers, Date Code, Serial Numbers,

- Any Customer Credits that are still unused,

- and if a payment (Receipt) was made, the payment information is shown.

An example of a SimpleManufacturing™ Receivable or Unpaid Invoice is shown below.

Choosing SimpleManufacturing™ as your next ERP / MRP Business Software Solution

The ERP Software you choose now will determine your company’s success. Please pay particular attention to its scalability, current features, and ability to be modified to meet your future business needs. Our flexible approach, focusing on efficiency and seamless integration with your existing processes, with the expectation of change, provides a long-lasting solution.

Call Now for a Free DEMO!

858-335-6421