Bill of Material (BOM) Management

Prepare and Manage Bill of Material (BOMs) with Ease in our Bill of Material Management module. Accurate, thorough, updated bill of materials improves decision-making and facilitates efficient production processes. Book A DemoBill of Material (BOM) is absolutely essential for manufacturing companies.

Here’s why:

Accuracy and Efficiency:

Bill Of Material ensure that all components are accounted for, which reduces the chances of errors and ensures that the manufacturing process is smooth and efficient.

Cost Management:

A detailed Bill Of Material helps in tracking the cost of each component, which in turn helps in budgeting and financial planning.

Inventory Control:

By listing all the materials needed, BOMs help in maintaining optimal inventory levels and preventing both shortages and excess stock.

Production Planning:

Bill Of Material provide a clear roadmap of the production process, helping in scheduling and resource allocation.

Quality Control:

Detailed Bill Of Material ensure that the right components are used, which helps in maintaining the quality of the final product.

Traceability:

Bill Of Materialmake it easier to trace the origin of components and materials, which is crucial for compliance and quality assurance.

Collaboration:

Bill Of Material serve as a common reference point for various teams, including engineering, manufacturing, and procurement, facilitating better communication and collaboration.

Every Bill of Material (BOM) should have specific details to ensure clarity and efficiency in the manufacturing process.

Here are the key elements each Bill Of Material must include:

Bill Of Material Level:

This indicates the hierarchy of the items. It helps in understanding the structure and components of the product.

Part Number:

A unique identifier for each item. It ensures that everyone refers to the same component without confusion.

Part Name:

A descriptive name for each item, making it easier to understand what the part is.

Quantity:

The number of each item required for the assembly or product.

Unit of Measure:

Specifies how the item is measured (e.g., pieces, meters, kilograms).

Description:

A detailed description of the part, including any specifications or requirements.

Procurement Type:

Indicates whether the part is purchased, manufactured in-house, or subcontracted.

Lead Time:

The time it takes to procure or manufacture the item.

Cost:

The cost of each item, helping in budgeting and financial planning.

Supplier Information:

Details about the supplier of the part, including contact information and part numbers.

Revision Level:

The version of the part, ensuring that the latest design or specification is used.

Assembly Instructions:

Any specific instructions or notes for assembling the part.

Including these details in a Bill Of Material ensures that all aspects of the manufacturing process are covered, reducing the risk of errors and improving overall efficiency.

Bill of Material (BOM) is absolutely essential for manufacturing companies.

That is why it is included in SimpleManufacturing™!

Our Bill Of Material Management Features

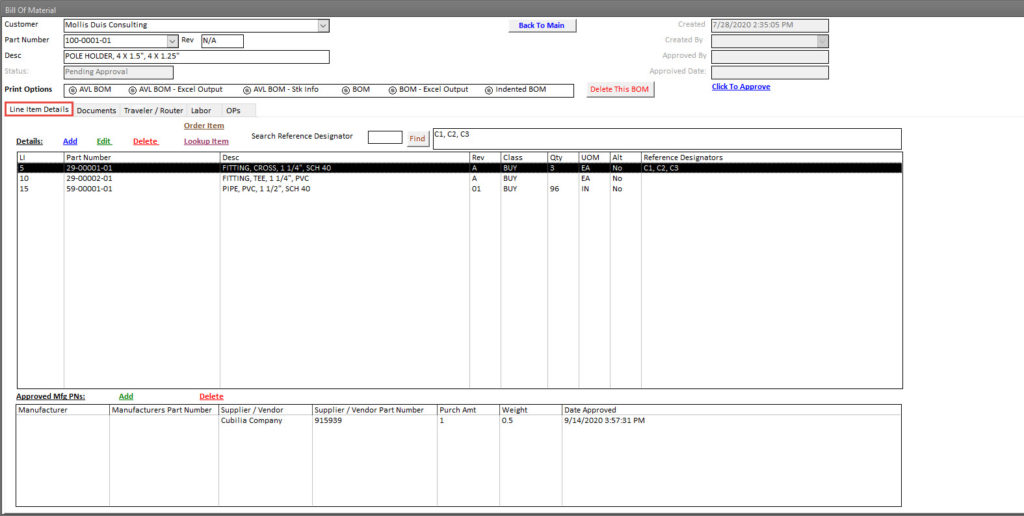

Common Bill Of Material Information

Part Number, Description, Revision Level and Unit of Measure

Common Line-Item Information

Line Item, Part Number, Description, Revision Level, Quantity and Unit of Measure Required, Procurement Type (Make, Buy, Phantom)

Primary / Alternate Parts

Identify Primary Part Number with ability to add alternate options per line item

Approved Vendor / Manufacture Part Numbers List

Add All Approved Vendor / Supplier Part Numbers of Each Line Item.

Document Links

Ability to Add Assembly Drawings, Routers, Work Instructions, Gerbers, X-Y Data, CAD Files, Customers Bill of Material, etc.

Router / Traveler / Process Work Flows

Create and Manage Router / Traveler / Process Work-Flow

Reference / Drawing Location

Add reference to Line-Item Part Location on Drawing, Layout, Fixture, etc.

Review / Approval Options

Ability to Identify and Document Reviewer and Approver Bill of Material

Reports

View AVL Bill Of Material, Indented Bill Of Material, Inventory Availability, Export to Excel Options

Comprehensive Search

Search by Bill Of Material Part Numbers, Component Line Items, Vendor Part Numbers, Revision Levels, and many more…!

Data Change History

When not Using Change Order Module, captures all changes made – What, Is / Was, Who and When

Labor / Outside Processing Standards

Ability to Add Labor Standards of Each Operational Step and Outside Processing Standard Cost.

Call Now for a Free DEMO!

858-335-6421