Quoting Management

Preparing and Tracking Quotes, Request for Quotes and Estimates with EaseUtilize the existing Customer, Part and Process List to efficiently prepare Quotes and Estimates in our Quote Management module.

When quoting for manufacturing, there are several key necessities to ensure an accurate and comprehensive quote.

These typically include:

Product Specifications:

Detailed drawings, designs, or technical specifications of the product to be manufactured. This includes dimensions, materials, tolerances, and any special requirements (e.g., finishes, surface treatments).

Quantity:

The number of units to be produced. Quantity can significantly affect pricing, as higher volumes often reduce the per-unit cost due to economies of scale.

Materials:

The type and grade of materials required for production, as material costs can vary significantly. This includes considerations like raw materials, secondary materials (e.g., fasteners, adhesives), and any unique material requirements (e.g., heat-resistant or corrosion-resistant materials).

Lead Time:

The time frame required for production, including any setup time, machining, assembly, or testing. This also includes the timeline for sourcing materials and shipping.

Production Process:

Whether the product will be made using machining, casting, molding, 3D printing, or other processes. The complexity of the production method can impact the cost.

Tooling:

Whether any new tools, dies, or molds are required for manufacturing. Custom tooling costs can add to the upfront costs.

Labor Costs:

The estimated amount of labor required for production, which depends on the complexity of the process and the skill levels needed. This could involve setup, machine operation, assembly, and quality control.

Overhead Costs:

These can include costs related to factory maintenance, equipment depreciation, utilities, and administrative support, which should be accounted for in the quote.

Shipping and Packaging:

Cost for shipping the final product to the customer or a designated location, including any special packaging requirements to ensure safe transit.

Testing and Quality Control:

Any testing or inspection requirements that may be needed to ensure the product meets specified standards. This could include material testing, performance testing, or visual inspections.

Compliance and Certification:

If the product needs to meet any industry-specific regulations or certifications (e.g., ISO standards, FDA approvals), these requirements should be factored into the quote.

Payment Terms:

Clear terms regarding when payments are due, deposits, or installment plans.

Risk Factors and Contingencies:

Consideration of potential risks such as price fluctuations in materials, production delays, or other unforeseen circumstances. A contingency budget can help manage these risks.

A well-rounded quote takes into account all of these factors to ensure a clear understanding of the project scope and costs for both the manufacturer and the customer.

The efficiency, thoroughness and management of quotes and estimates matters.

That is why it is included in SimpleManufacturing™!

Our Quotation Management Features

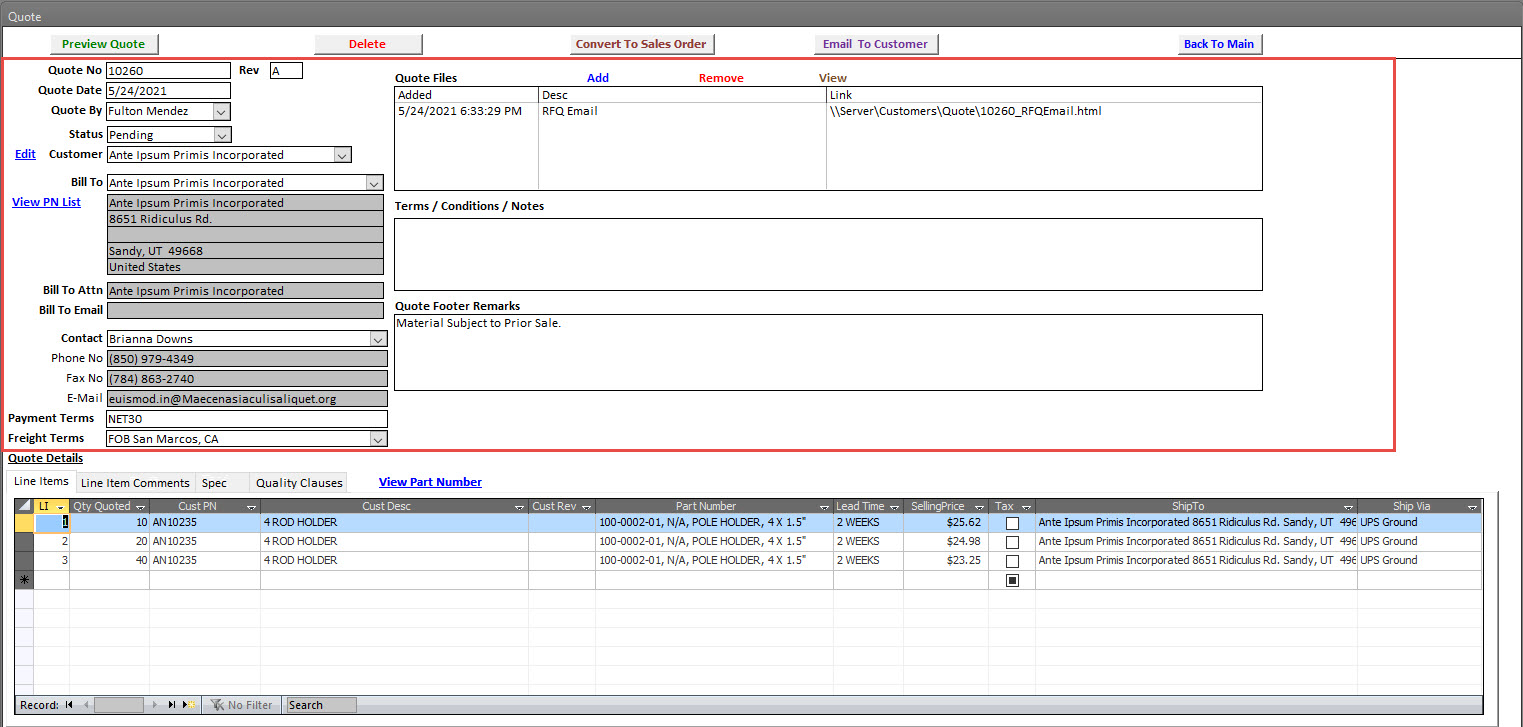

Comprehensive Quote Details

Quantities, Deliveries, Lead Times, Specifications, Materials, Tooling, Labor, Material, NRE, Outside Processing and Overhead Costs

Link Files in Quote

Link Drawings, Emails, Request For Quote (RFQ), Terms and Conditions, Material Quotes, Labor Estimates

Quality Clauses

Identify and Record Customer’s Quality Clauses

Bill Of Materials (BOMs)

Ability to Prepare Bill of Materials for Easy Transfer when Order Received

Process Flow

Ability to Prepare Process Flow for Easy Transfer when Order Received

Robust Reporting

Generate detailed reports of quotes won and lost, outstanding quotes and quote history.

Automation

Single-Click preparation Email quote response with Electronic Signatures.

Import Supplier Quotes

Ability to Import Supplier Quotes and Identify best Pricing Options

Comprehensive Search Options

Search By Customers, Dates, Status, Delivery Dates, Part Numbers, Request for Quote (RFQ) Number, etc.

Call Now for a Free DEMO!

858-335-6421